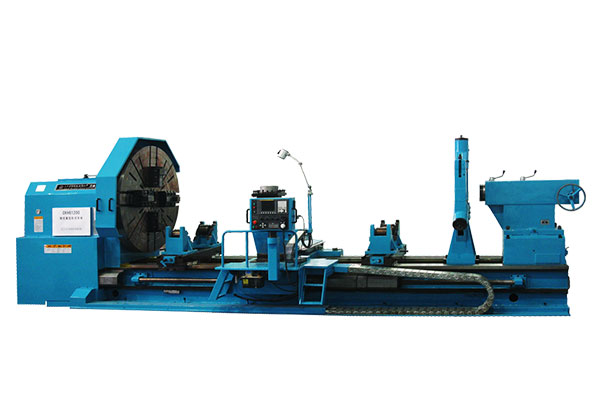

conventional lathes china manufacturer:

The conventional lathe machine is universal lathe which is suitable for different kinds of industries. The conventional lathe has more flexibility in machining than other machines.

Functions:

1. Outer cylinder turning, cone turning, curved surface turning, inner hole turning, end face turning, chamfering and other machining;

2. Metric thread, inch thread, modular thread, pitch thread cutting;

3. Shot and long taper turning;

4. Drilling, boring, jacking and grooving;

5. Left hand turning and right hand turning;

6. Even grinding and milling with grinding and milling attachment.

Characteristics:

1. Our conventional lathe’ load weight is better than others with similar specification. The max. workpiece that can be processed by our conventional lathe is 1500kg, 2000kg, 2500kg,3000kg, 6000kg and 8000kg;We also have heavy duty conventional lathe with max. workpiece weight 10 ton to 80 ton.

2. The high torsion resistant horizontal bed is made of high quality cast iron, the guide is high frequency induction quenched with guide width 500 mm, 600 mm and 755 mm;

3. Distance between centers up to from 750 mm to 12000 mm, any distance can be customized;

4. Our lathe bed is equipped with tilt chip discharge, much easy for chip removing;

5. The TSF soft strip is applied to the guide which greatly reduces the friction coefficient and prolong the service life;

6. The motion pairs of the conventional lathe are automatically lubricated by the centralized automatic lubrication pump;

7. Transmission system, hydraulic system and electrical system are stable enough to ensure good machine performance;

8. Equipped with mechanical interlocking protection device to ensure safety;

Parameter:

Span of guideway: 500mm & 600mm

| Item | Unit | CW6163B | CW6263B | CW6180B | CW6280B | CW6194B | CW6294B | CW6180 | CW61100 | |

| Capacity | Swing over bed | mm | φ630 | φ800 | φ940 | φ800 | φ1000 | |||

| Swing over carriage | mm | φ350 | φ520 | φ660 | φ480 | φ680 | ||||

| Swing over gap | - | - | φ830 | - | φ1000 | - | φ1140 | - | - | |

| Max. length of workpiece | mm | 1500/2000/3000 | 1500/2000/3000 | 1500/2000/3000 | 1500/2000/3000 | 1500/2000/3000 | ||||

| Max. turning length | mm | 1350/1850/2850 | 1350/1850/2850 | 1350/1850/2850 | 1350/1850/2850 | 1350/1850/2850 | ||||

| Span of guideway | mm | 550 | 550 | 550 | 600 | 600 | ||||

| Max. weight of workpiece | t | 1.5/3 | 1.5/3 | 1.5/3 | 2/4 | 2/4 | ||||

| Spindle | Spindle nose type | - | C11 | C11 | C11 | C11/C15 | C11/C15 | |||

| Center taper | - | MT5 | MT5 | MT5 | MT6 | MT6 | ||||

| Spindle bore | mm | φ100 | φ100 | φ100 | φ100/φ140 | φ100/φ140 | ||||

| No. of spindle speeds | - | 18 | 18 | 18 | 18/6 | 18/6 | ||||

| Range of spindle speeds | r/min | 7.5-1000 | 6-800 | 6-800 |

Forward: 6-750; Reverse:10-775 |

Forward: 6-750; Reverse:10-775 | ||||

| Toolpost | Cross section of tool shank | mm | 30*30 | 30*30 | 30*30 | 32*32 | 32*32 | |||

| Max.stroke of upper toolpost | mm | 200 | 200 | 200 | 200 | 200 | ||||

| Max. stroke of lower toolpost | mm | 440 | 540 | 570 | 500 | 500 | ||||

| Feed | No. of longitudinal and transverse feeding | - | 64 kinds each | 64 kinds each | 64 kinds each | 64 kinds each | 64 kinds each | |||

| Ratio of transverse feed to longitudinal feed | - | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | ||||

| No. and rang of metric threads | - | 50; 1-240 | 50; 1-240 | 50; 1-240 | 50; 1-240 | 50; 1-240 | ||||

| No. and rang of inch threads | - | 26; 14-1 | 26; 14-1 | 26; 14-1 | 26; 14-1 | 26; 14-1 | ||||

| No. and rang of modulus threads | - | 53; 0.5-44 | 53; 0.5-44 | 53; 0.5-44 | 53; 0.5-120 | 53; 0.5-120 | ||||

| No. and rang of diameter pitch threads | - | 24; 28-1 | 24; 28-1 | 24; 28-1 | 24; 28-1 | 24; 28-1 | ||||

| Tailstock | Tailstock quill diameter | mm | 100 | 100 | 100 | φ100 | φ100 | |||

| Tailstock quill taper | - | MT5 | MT5 | MT5 | MT6 | MT6 | ||||

| Tailstock quill effective stroke | mm | 250 | 250 | 250 | 250 | 250 | ||||

| Power system | Main motor power | kW | 11 | 11 | 11 | 11 | 11 | |||

| Rapid traverse motor power | kW | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | ||||

| Others | Width*Height | mm | 1393*1537 | 1473*1622 | 1430*1690 | 1450*1730 | 1450*1830 | |||

| Length | mm | 3725/4225/5225 | 3725/4225/5225 | 3725/4225/5225 | 3670/3985/5165 | 3670/3985/5165 | ||||

| Net weight | kg | 3700/4200/4700 | 3900/4400/4900 | 4400/4900/5400 | 4900/5100/5500 | 5400/5600/6000 | ||||

| Note: swing over bed/swing over gap/distance between centers (750mm-12000mm) can be customized. | ||||||||||

Application:

Optional accessories:

1. Gap bed;

2. Digital readout (DRO);

3. Taper attachment;

4. Grind attachment vacuum dust collector;

5. Milling attachment;

6. Rotary tailstock, motorized tailstock, pneumatic tailstock and hydraulic tailstock;

7. Non-standard chuck and steady rest;

8. Tailstock chuck;

9. Others.