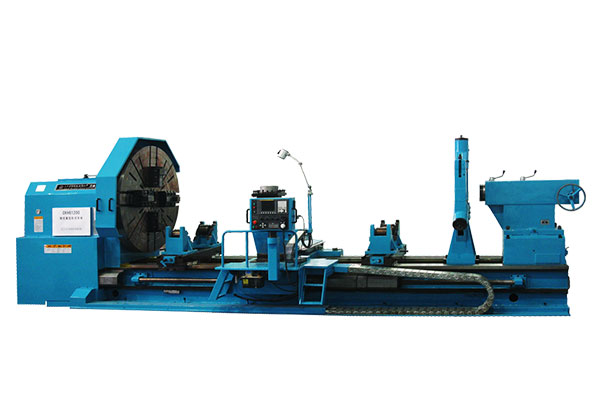

conventional lathes china manufacturer:

The conventional lathe machine is universal lathe which is suitable for different kinds of industries. The conventional lathe has more flexibility in machining than other machines.

Features:

Span of guideway: 755mm

● The max. workpiece for our lathe is 6000 kg.

● Our chuck is φ1000 mm made by Hohhot, the best and most famous chuck manufacturer in China, our chuck is durable.

● Our lathe guide is quenched by induction quenching device, hardened layer thickness is 2-3mm, hardness is 52 HRC.

● There are oblique chip outlets in our lathe bed, easy for chip removing.

● DRO, quick change toolpost, grinding attachment, milling power head, rotary tailstock, motorized tailstock are for option.

Span of guideway: 970mm

● The max. workpiece for our lathe is 10 ton.

● Our lathe guide is quenched by induction quenching device, hardened layer thickness is 2-3mm, hardness is 52 HRC.

● We have Germany made high precision lathe guide grinding machine to ensure the guide precision.

● Our chuck is K78 series φ1250 mm heavy duty chuck made by Hohhot, the best and most famous chuck manufacturer in China.

● Motorized tailstock.

● DRO, grinding attachment, milling power head, rotary tailstock, tailstock chuck are for option.

Parameter:

Span of guideway: 755mm

| Item | Unit | CW61100B | CW61125B | CW61140B | CW61160B | |

| Capacity | Swing over bed | mm | φ1000 | φ1250 | φ1400 | φ1640 |

| Swing over carriage | mm | φ615 | φ865 | φ1015 | φ1250 | |

| Max. length of workpiece | mm | 1500/3000/5000/6000 | 1500/3000/5000/6000 | 1500/3000/5000/6000 | 1500/3000/5000/6000 | |

| Max. turning length | mm | 1300/2800/4800/5800 | 1300/2800/4800/5800 | 1300/2800/4800/5800 | 1300/2800/4800/5800 | |

| Span of guideway | mm | 755 | 755 | 755 | 755 | |

| Max. weight of workpiece | t | 6 | 6 | 6 | 6 | |

| Spindle | Spindle nose type | - | A2-15 | A2-15 | A2-15 | A2-15 |

| Front taper of spindle hole | - | 1:20/Metric 140 | 1:20/Metric 140 | 1:20/Metric 140 | 1:20/Metric 140 | |

| Spindle bore | mm | φ130 | φ130 | φ130 | φ130 | |

| No. of spindle speeds | - |

Forward 21; Reverse 12 |

Forward 21; Reverse 12 |

Forward 21; Reverse 12 |

Forward 21; Reverse 12 | |

| Range of spindle speeds | r/min |

Forward 3.15-315; Reverse 3.5-291 |

Forward 3.15-315; Reverse 3.5-291 |

Forward 3.15-315; Reverse 3.5-291 |

Forward 3.15-315; Reverse 3.5-291 | |

| Toolpost | Cross section of tool shank | mm | 45*45 | 45*45 | 45*45 | 45*45 |

| Max.stroke of upper Toolpost | mm | 300 | 300 | 300 | 300 | |

| Max. stroke of lower Toolpost | mm | 520 | 580 | 580 | 630 | |

| Feed |

No. of longitudinal and transverse feeding | - | 56 kinds each | 56 kinds each | 56 kinds each | 56 kinds each |

| No. and rang of metric threads | - | 44; 1-120 | 44; 1-120 | 44; 1-120 | 44; 1-120 | |

| No. and rang of inch threads | - | 31; 28-1/4 | 31; 28-1/4 | 31; 28-1/4 | 31; 28-1/4 | |

| No. and rang of modulus threads | - | 45; 0.5-60 | 45; 0.5-60 | 45; 0.5-60 | 45; 0.5-60 | |

|

No. and rang of diameter pitch threads | - | 38; 1/2-56DP | 38; 1/2-56DP | 38; 1/2-56DP | 38; 1/2-56DP | |

| Tailstock | Tailstock quill diameter | mm | 160 | 160 | 160 | 160 |

| Tailstock quill taper | - | MT6 | MT6 | MT6 | MT6 | |

| Tailstock quill max. stroke | mm | 300 | 300 | 300 | 300 | |

| Others | Main motor power | kW | 22 | 22 | 22 | 22 |

| Width*Height | mm | 2150*1700 | 2150*1825 | 2150*2100 | 2150*2150 | |

| Length | mm | 4600/6100/8100/9100 | 4600/6100/8100/9100 | 4600/6100/8100/9100 | 4600/6100/8100/9100 | |

| Net weight | kg |

9200/10700/12100/ 12800 |

10200/11800/14800/ 15500 |

10300/11900/14900/ 15600 |

10500/12100/15100/ 16600 | |

| Note: swing over bed/swing over gap/distance between centers (1500mm-12000mm) can be customized. | ||||||

Span of guideway: 970mm

| Item | Unit | CW61125 | CW61140 | CW61160 | |

| Capacity | Swing over bed | mm | φ1250 | φ1400 | φ1600 |

| Swing over carriage | mm | φ865 | φ1010 | φ1210 | |

| Max. length of workpiece | mm | 3000/4000/5000/6000 | 3000/4000/5000/6000 | 3000/4000/5000/6000 | |

| Max. turning length | mm | 2800/3800/4800/5800 | 2800/3800/4800/5800 | 2800/3800/4800/5800 | |

| Span of guideway | mm | 970 | 970 | 970 | |

| Max. weight of workpiece | t | 10 | 10 | 10 | |

| Spindle | Front taper of spindle hole | - | Metric 140 | Metric 140 | Metric 140 |

| Spindle bore | mm | φ130 | φ130 | φ130 | |

| No. of spindle speeds | - |

Forward 21; Reverse 12 |

Forward 21; Reverse 12 |

Forward 21; Reverse 12 | |

| Range of spindle speeds | r/min | Forward 3.15-315; Reverse 3.5-291 | Forward 3.15-315; Reverse 3.5-291 | Forward 3.15-315; Reverse 3.5-291 | |

| Toolpost | Cross section of tool shank | mm | 45*45 | 45*45 | 45*45 |

| Max.stroke of upper Toolpost | mm | 300 | 300 | 300 | |

| Max. stroke of lower Toolpost | mm | 650 | 650 | 650 | |

| Feed | No. of longitudinal and transverse feeding | - | 56 kinds each | 56 kinds each | 56 kinds each |

| No. and rang of metric threads | - | 44; 1-120 | 44; 1-120 | 44; 1-120 | |

| No. and rang of inch threads | - | 31; 28-1/4 | 31; 28-1/4 | 31; 28-1/4 | |

| No. and rang of modulus threads | - | 45; 0.5-60 | 45; 0.5-60 | 45; 0.5-60 | |

| No. and rang of diameter pitch threads | - | 38; 1/2-56DP | 38; 1/2-56DP | 38; 1/2-56DP | |

| Tailstock | Tailstock quill diameter | mm | 220 | 220 | 220 |

| Tailstock quill taper | - | MT6 | MT6 | MT6 | |

| Tailstock quill max. stroke | mm | 300 | 300 | 300 | |

| Others | Main motor power | kW | 22 | 22 | 22 |

| Width*Height | mm | 1995*2175 | 1995*2325 | 1995*2525 | |

| Length | mm | 6020/7020/8020/9020 | 6020/7020/8020/9020 | 6020/7020/8020/9020 | |

| Net weight | kg | 14500/15800/17000/18300 | 15000/16300/17500/18800 | 15500/16800/18000/19300 | |

| Note: swing over bed/distance between centers (3000mm-16000mm) can be customized. | |||||

Optional accessories:

1. Gap bed;

2. Digital readout (DRO);

3. Taper attachment;

4. Grind attachment vacuum dust collector;

5. Milling attachment;

6. Rotary tailstock, motorized tailstock, pneumatic tailstock and hydraulic tailstock;

7. Non-standard chuck and steady rest;

8. Tailstock chuck;

9. Others.