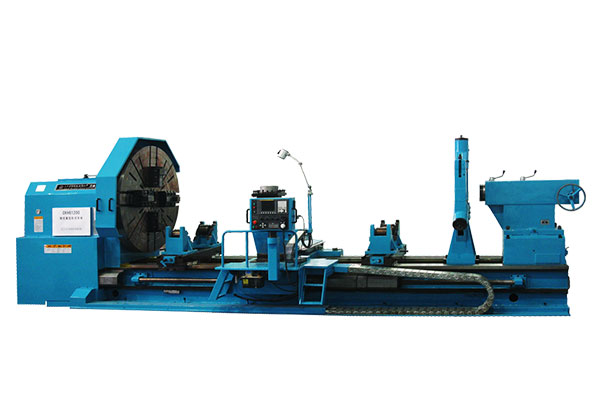

mini cnc lathe machines:

The small lathe adopts the mechanical and electrical integration design, which with reasonable structure, widely application, simple operation and beautiful appearance. It can achieve automatic control, automatically process a variety of parts of the inner and outer ring, end face, slot, any conical surface, spherical and other public Inch cylinders, taper threads, etc.

Advantages of small cnc lathes:

1.High precision (processing accuracy 0.01mm).Repeat positioning(0.01mm)

2.Rail surface is bysupersonic frequency quenching.

3. Thedynamic performance is excellent.

4. The operation is easr for workers

5. Every lathe can configure automatic feeding device whichcan achieve fully automation.

Application:

Technical parameters:

| Item | Unit | CK0640 | CK0660 | CKD6136 | CKD6140/A | CKQ6140 | CKQ6150 | CKQ6161 | CKQ6166 | CKQ6180 | |

| Capacities | Swing over bed | mm | φ300 | φ400 | φ360 | φ400 | φ400 | φ500 | φ610 | φ660 | 800 |

| Swing over carriage | mm | φ120 | φ150 | φ200 | φ220 | φ210 | φ280 | φ370 | φ400 | φ540 | |

| Max. length of workpiece | mm | 180 | 200 | 750/1000 | 750/1000 | 750/1000/2000 | 750/1000/2000 | 750/1000/2000 | 750/1000/2000 | 750/1000/2000 | |

| Max. turning length | mm | 180 | 200 | 600/850 | 600/850 | 600/850/1850 | 600/850/1850 | 600/850/1850 | 600/850/1850 | 600/850/1850 | |

| Span of guideway | mm | 260 | 260 | 312 | 312 | 400 | 400 | 400 | 400 | 400 | |

| Spindle | Spindle nose type | - | - | - | C6 | C6 | C6/D8 | C6/D8/D8 | C6/D8/D8 | C6/D8/D8 | C6/D8/D8 |

| Spindle center taper | - | - | - | MT6 | MT6 | MT6/φ90 1:20 |

MT6/ φ90 1:20/ φ113 1:20 |

MT6/ φ90 1:20/ φ113 1:20 |

MT6/ φ90 1:20/ φ113 1:20 |

MT6/ φ90 1:20/ φ113 1:20 | |

| Spindle bore | mm | φ40 | φ48 | φ52 | φ52 | φ52/φ80 | φ52/φ80/φ105 | φ52/φ80/φ105 | φ52/φ80/φ105 | φ52/φ80/φ105 | |

| Range of spindle speeds | r/min | 3000 | 2800 | 1600/3000 | 1600 | 1500/1600 | 1500/1600 | 1500/1600 | 1500/1600 | 1500/1600 | |

| Chuck size | mm | Spring collet | Spring collet | 200 | 250 | 250 | 250 | 250 | 250 | 250 | |

| Turret | Cross section of tool shank | mm | 16*16 | 16*16 | 20*20 | 20*20 | 25*25 | 25*25 | 25*25 | 25*25 | 25*25 |

| Turret type | - | Gang tool | Gang tool | V4 | V4 | V4 | V4 | V4 | V4 | V4 | |

| Feed | Min. feed of X-axis/Z-axis | mm | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Feed speed range | mm/min | 1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 | |

| Rapid traverse speed of X-axis/Z-axis | mm/min | 6000/8000 | 6000/8000 | 4000/6000 | 4000/6000 | 4000/6000 | 4000/6000 | 4000/6000 | 4000/6000 | 4000/6000 | |

| Max. stroke of X-axis | mm | 190 | 220 | 210 | 210 | 250 | 260 | 320 | 340 | 410 | |

| Tailstock | Tailstock quill diameter | mm | - | φ52 | φ60 | φ60 | φ75 | φ75 | φ75 | φ75 | φ75 |

| Tailstock quill taper | - | - | MT4 | MT 4 | MT 4 | MT 5 | MT 5 | MT 5 | MT 5 | MT 5 | |

| Tailstock quill max. stroke | mm | - | 90 | 100 | 100 | 150 | 150 | 150 | 150 | 150 | |

| Power system | Main motor power | kW | 4 | 4 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Others | CNC system | - | GSK928TD-L | GSK928TD-L | GSK928TD-L | GSK928TD-L | GSK928TD-L | GSK928TD-L | GSK928TD-L | GSK928TD-L | GSK928TD-L |

| Width * Height | mm | 1200*1600 | 1000*1600 | 1240*1700 | 1240*1700 | 2550/2750/3700 | 2550/2750/3700 | 2550/2750/3700 | 2550/2750/3700 | 2550/2750/3700 | |

| Length | mm | 1600 | 1700 | 2170/2415 | 2170/2415 | 1550*1700 | 1550*1700 | 1550*1800 | 1550*1900 | 1550*2000 | |

| Net weight | kg | 800 | 1100 | 1400/1500 | 1700/1800 | 2100/2200/2700 | 2120/2240/2740 | 2250/2400/2800 | 2300/2450/2880 | 2400/2550/2980 | |

| Note: swing over bed/swing over gap/distance between centers (750mm-3000mm) can be customized. | |||||||||||

Main configuration:

1. CNC system:GSK928, servomotoranddrive

2. 3-jawchuck

3. Fourstationelectrictoolpost

4. Manualtailstock

5. LED light

6.Spindle center, live center

7.Coolingsystem

8.Lightensystem

9.Automaticlubricationsystem