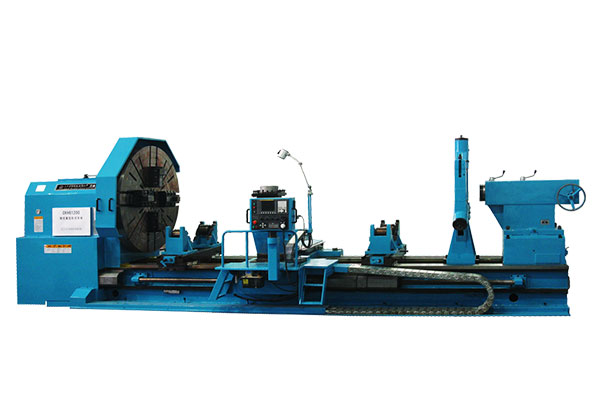

High Precision CNC Piston Lathe:

This CNC vertical piston lathe/Vertical Piston Turner/CNC Piston Turner (Camless Oval Turn)adopts verticalstructureand left and right sliding plate structure, which is mainly used to process the special-shaped oval of piston skirt, ring groove, top surface and ring groove special-shaped chamfers;

Equipped with double-cylinder linear servo toolpost for processing the convex outer oval or other complex shapes of the outer circle of the piston. The double cutting tools adopt different materials or shapes to turn different pistons with different materials;

The software is powerful. By modeling and G code combination editing, it can complete all kinds of special-shaped outer ovals, including standard oval, oval superposition eccentric circle, eccentric oval, rotating oval, etc.

Features:

●Genuine CNC piston lathe forcamless oval turning.

● Piston diameter range 50-200 mm, piston length up to 200 mm.

● 6 mm super big ovality amount.

● Vertical structure with symmetrical spindle structure, thermal deformation has little effect on the consistency of machining accuracy, effectively eliminating the dimensional error caused by the temperature rise of the spindle.

● Our lathe is equipped with vertical piston clamping fixture, accurate and close contact between the piston stop and the fixture's reference plane ensures stable machining accuracy and convenient clamping.

● Lathe bed is designed with high seismic performance, smooth chip removal performance, compact size and high rigidity, especially suitable for high-strength automated processing of large and medium batch pistons.

● The processes of finish grooving, finish top surface turning, finish skirt oval turning can be completed simultaneously, avoiding secondary clamping of pistons, effectively improving pistons processing accuracy, reducing logistics time for pistons transition, and improving processing efficiency.

● X1, Z1, X2, Z2, W2 and C, total of 6 coordinate axes.

● 5.5kW high-power and high-torque servo main motor.

● Linear motor with high-acceleration and high-frequency cutting is used.

Advantages of piston lathe:

(1) It adopts FANUC 31i control system, and applies the 15" large monitor, super high speed processing mass control program to nanoscale precision of calculation for the unit and the most advanced servo technology.

(2) It can realizehigh speed and high precision machining.

(3) According to the different piston workpiece, the machine is designed for special piston tooling to ensure the machining precision of the piston.

(4) The lathe adopts double linear servo tool holder, with high positioning accuracy, high reflection frequency and large driving force.

(5) It is capable of cutting the pistons of any material.

Application:

Customer case:

Technical Parameter:

| Item | Unit | VPL15 | VPL20 | |

| Capacities | Max. piston diameter | mm | φ150 | φ200 |

| Max. piston length | mm | 160 | 200 | |

| Max. pison ovality amount | mm | 6 | 6 | |

| Spindle | Max. spindle speed | r/min | 4000 | 3000 |

| Spindle nose type | - | A2-6 | A2-6 | |

| Main motor power | kW | 5.5 | 5.5 | |

| Fixture | Fixture type | - | hydraulic type | pneumatic type |

| Toolpost | Toolpost type | - | Gang tool type | Gang tool type |

| Tool quantity | pcs | 5 | 5 | |

| X1 axis | X1-axis stroke | mm | 150 | 115 |

| X1-axis servo motor power | kW | 1.4 | 0.9 | |

| Rapid traverse speed of X1-axis | m/min | 12 | 12 | |

| X2 axis/ Ovality generator | X2-axis stroke | mm | 16 | 15 |

| X2-axis linear motor power | kW | 1.44 | 1.5 | |

| Rapid traverse speed of X2-axis | m/min | 12 | 12 | |

| Z axis | Z-axis stroke | mm | 280 | 350 |

| Z-axis servo motor power | kW | 3 | 1.5 | |

| Rapid traverse speed of Z-axis | m/min | 12 | 12 | |

| Tailstock | Tailstock stroke | mm | 260 | 350 |

| Accuracy | Repeat positioning accuracy of X2-axis | mm | ± 0.0005 | ± 0.001 |

| Positioning accuracy of X2-axis | mm | ± 0.001 | ± 0.005 | |

| Positioning accuracy of C-axis | ° | 0.001 | 0.003 | |

| Others | CNC system | - | Fanuc 31i | COPLEY+piston curved surface control software |

| Length*Width*Height | mm | 1300*2400*2500 | 2800*1600*2500 | |

| Net weight | kg | 3500 | 5000 |