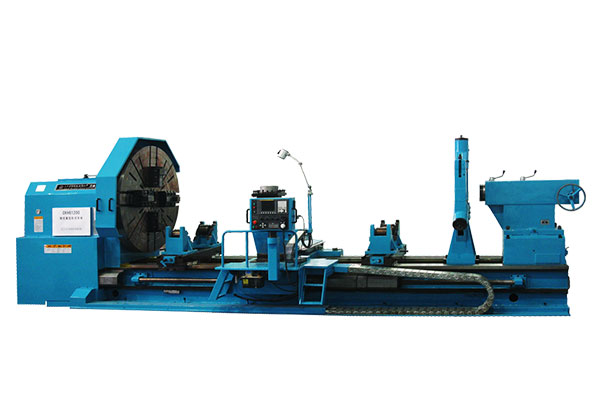

Heavy duty lathe machine:

The heavy duty lathe including CNC heavy duty lathe and conventional heavy duty lathe:

Heavy duty lathepertain to large scale horizontal lathe. Heavy duty lathe is suitable for processinglarge size workpiece up to maximum. The spindle of heavy duty lathe is driven by high power motor. Heavy duty lathe could achieve high precision heavy cutting at low rotational speed. The bearing capacity of heavy duty lathe is between 16 tons and 63 tons. Theheavy duty lathe including CNC heavy duty lathe and conventional heavy duty lathe:CNC heavy duty lathes:This CNC heavy-duty lathe belongs to horizontal lathe, which is not only apply for different materials of shaft parts, cylindrical and disc-shaped parts, but also widely used for boring, car boring inside and outside the cone, and a variety of threads. The lathe has advantages such as best adaptability, high efficiency, high precision and high quality.

Conventional heavy lathes:This machine tool belongs to heavy lathe machine, the maximum bearing-load is 16/32 tons, and it adopts the rectangular guide rail, which can be able to cut the end section of all kinds of parts, outer circle, inner hole and metric system, English system, modulus, state thread.

Features:1.Heavy load, high precision, reasonable structure, wide adaptability and convenient operation.

Features:1.Heavy load, high precision, reasonable structure, wide adaptability and convenient operation.

2.Semi closed loop control system.

3. With super large bed and head box structure support to ensure the machine to run the best rigid when it cuts various parts.

4.The feed system is connected with the main drive through the optical bar.

5.High accuracy, long life and good retention.

Application:

Patameter:

Span of guideway:1100mm

| Item | Unit | C61125 | C61160 | C61180 | C61200 | |

| Capacity | Swing over bed | mm | φ1250 | 1600 | φ1800 | φ2000 |

| Swing over carriage | mm | φ900 | φ1250 | φ1450 | φ1650 | |

| Max. length of workpiece | mm | 3000/4000/5000/6000 | 3000/4000/5000/6000 | 3000/4000/5000/6000 | 3000/4000/5000/6000 | |

| Max. turning length | mm | 2800/3800/4800/5800 | 2800/3800/4800/5800 | 2800/3800/4800/5800 | 2800/3800/4800/5800 | |

| Span of guideway | mm | 1100 | 1100 | 1100 | 1100 | |

| Structure of guideway | - |

Rectangular 2 guideways |

Rectangular 2 guideways |

Rectangular 2 guideways |

Rectangular 2 guideways | |

| Max. weight of workpiece | t | 16 | 16 | 16 | 16 | |

| Spindle | Front taper of spindle hole | - | Metric 140 | Metric 140 | Metric 140 | Metric 140 |

| Spindle bore | mm | φ100 | φ100 | φ100 | φ100 | |

| No. of spindle speeds | - | Forward 21; Reverse 12 | Forward 21; Reverse 12 | Forward 21; Reverse 12 | Forward 21; Reverse 12 | |

| Range of spindle speeds | r/min |

Forward 3.15-315; Reverse 3.5-291 |

Forward 3.15-315; Reverse 3.5-291 |

Forward 3.15-315; Reverse 3.5-291 |

Forward 3.15-315; Reverse 3.5-291 | |

| Toolpost | Cross section of tool shank | mm | 50*50 | 50*50 | 50*50 | 50*50 |

| Max.stroke of upper Toolpost | mm | 360 | 360 | 360 | 360 | |

| Max. stroke of lower Toolpost | mm | 740 | 850 | 900 | 900 | |

| Feed |

No. of longitudinal and transverse feeding | - | 56 kinds each | 56 kinds each | 56 kinds each | 56 kinds each |

| No. and rang of metric threads | - | 44; 1-120 | 44; 1-120 | 44; 1-120 | 44; 1-120 | |

| No. and rang of inch threads | - | 31; 28-1/4 | 31; 28-1/4 | 31; 28-1/4 | 31; 28-1/4 | |

| No. and rang of modulus threads | - | 45; 0.5-60 | 45; 0.5-60 | 45; 0.5-60 | 45; 0.5-60 | |

|

No. and rang of diameter pitch threads | - | 38; 1/2-56DP | 38; 1/2-56DP | 38; 1/2-56DP | 38; 1/2-56DP | |

| Tailstock | Tailstock quill diameter | mm | 260 | 260 | 260 | 260 |

| Tailstock quill taper | - | Metric 80 | Metric 80 | Metric 80 | Metric 80 | |

| Tailstock quill max. stroke | mm | 300 | 300 | 300 | 300 | |

| Others | Main motor power | kW | 30 | 30 | 30 | 30 |

| Width*Height | mm | 2058*2200 | 2130*2380 | 2330*2480 | 2430*2580 | |

| Length | mm | 6120/7120/8120/9120 | 6120/7120/8120/9120 | 6120/7120/8120/9120 | 6120/7120/8120/9120 | |

| Net weight | kg |

18300/19900/ 21500/23100 |

19800/21400/ 23000/24600 |

20300/21900/ 235000/25100 |

20800/22400/ 24000/25600 | |

| Note: swing over bed/distance between centers (3000mm-14000mm) can be customized. | ||||||

Span of guideway:1600mm

| Item | Unit | C61160 | C61200 | C61250 | |

| Capacity | Swing over bed | mm | φ1600 | φ2000 | φ2500 |

| Swing over carriage | mm | φ1250 | φ1600 | φ2000 | |

| Max. length of workpiece | mm | 8000/10000/12000/16000 | 8000/10000/12000/16000 | 8000/10000/12000/16000 | |

| Max. cutting force of single toolpost | kg | 8000 | 8000 | 8000 | |

| Total cutting force | kg | 6000 | 6000 | 6000 | |

| Max. cutting force | kg | 16000 | 16000 | 16000 | |

| Structure of guideway | - | Rectangular 3 guideways | Rectangular 3 guideways | Rectangular 3 guideways | |

| Span of guideway | mm | 1600 | 1600 | 1600 | |

| Max. weight of workpiece | t | 32 | 32 | 32 | |

| Spindle | Spindle speed | - | Stepless | Stepless | Stepless |

| Spindle taper hole angle | ° | 75 | 75 | 75 | |

| Spindle speed range | r/min | 0.8-160 | 0.8-160 | 0.8-160 | |

| Spindle taper hole | - | Metric 120, taper 1:7 | Metric 120, taper 1:7 | Metric 120, taper 1:7 | |

| Face plate diameter | mm | φ1600 | φ1800 | φ2000 | |

| Toolpost | Max. stroke of transverse toolpost | mm | 725 | 725 | 800 |

| Max. stroke of lower toolpost | mm | 600 | 600 | 600 | |

| Feed | Feed grades | - | 18 | 18 | 18 |

| Range of metric threads | mm | 2-40 | 2-40 | 2-40 | |

| Range of inch threads | - | 1-14 | 1-14 | 1-14 | |

| Range of modulus threads | mm | 1.5-20 | 1.5-20 | 1.5-20 | |

| Tailstock | Tailstock quill diameter | mm | φ300 | φ300 | φ300 |

| Tailstock quill taper | - | φ100 taper 1:7 | φ100 taper 1:7 | φ100 taper 1:7 | |

| Tailstock quill max. stroke | mm | 300 | 300 | 300 | |

| Others | Main motor power | kW | 75 | 75 | 75 |

| Width*Height | mm | 2479*2280 | 2579*2580 | 2679*2680 | |

| Length | mm | 13577/15577/17577/21577 | 13577/15577/17577/21577 | 13577/15577/17577/21577 | |

| Net weight | kg | 45000/48000/52000/58000 | 47000/50000/54000/59000 | 48000/51000/55000/60000 | |

| Note: swing over bed/distance between centers (5000mm-20000mm) can be customized. | |||||

Span of guideway:2090mm

| ITEMS | UNIT | C61250 | |

| Capacity | Swing over bed | mm | φ2500 |

| Swing over carriage | mm | φ2200 | |

| Length of workpiece | mm | 5000-20000 | |

| Max. torque of faceplate | N*m | 120000 | |

| Max. cutting force of single toolpost | N | 120000 | |

| Total cutting force | N | 200000 | |

| Span of guideway | mm | 2090 | |

| Structure of guideway | - | Rectangular 3 guideways | |

| Max. weight of workpiece | t | 63 | |

| Spindle | Spindle speed | - | Stepless |

| Spindle speed range | r/min | 0.5-125 | |

| Spindle taper hole | - | φ196.869; taper1:4 | |

| Face plate diameter | mm | φ2200 | |

| Toolpost | Max. stroke of X-axis | mm | 1000 |

| Rapid traverse speed of X-axis | mm/min | 3000 | |

| Rapid traverse speed of Z-axis | mm/min | 6000 | |

| Tailstock | Tailstock quill diameter | mm | φ560 |

| Tailstock quill stroke | mm | 200 | |

| Tailstock quill taper | mm | 75°, φ160 ( taper 1:4) | |

| Others | Main motor type | - | DC motor |

| Main motor power | Kw | 144; 540-1900r/min | |

| Note: swing over bed/distance between centers (5000mm-20000mm) can be customized. | |||