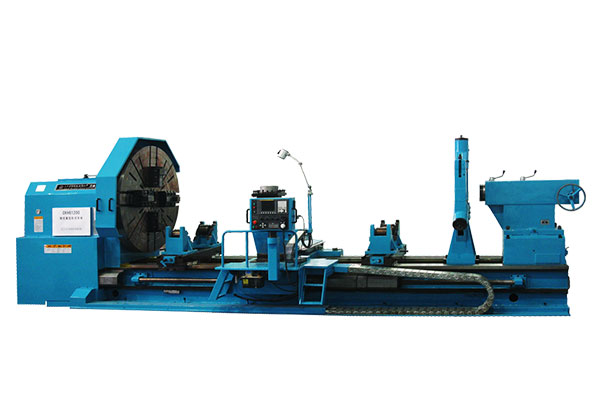

High performance CNC oil country lathe:

This high performance CNC oil country lathe is a special CNC slant bed lathe for threads processing of oil tubing and casing pipe. It is suitable for machining upsetting pipe and pipe without upsetting with an external diameter of 23/8"- 7" and length of 6-12.5 m.

The types of threads include LTC, STC, BTC and other special threads. Thread machining quality complies with API 5B standard.

The slant bed CNC pipe threading lathe is equipped with 2 tool holders (4 tools) for rough and fine turning of cone and thread, inner and outer chamfering and end face turning at the end of pipe simultaneously, which greatly enhances productivity and especially suitable for mass production. For example, it takes only about 50 seconds (from feeding to discharging) to finish one end of API 5DP drill pipe with diameter 51/2".

In order to enhance the rigidity and stability of the pipe in the process of machining, and to ensure that the machining precision meets the requirements, the lathe adopts a three-fulcrum clamping arrangement for the machined pipe. The end of the tube expander installed on the main shaft of the tube expander enters the end of the processed pipe for internal centering and clamping. External clamping of the machined pipe by two chucks mounted on both ends of the spindle at the headstock.

In order to improve the transmission accuracy and stability of the feed system and eliminate the clearance of mechanical movement, the lathe is equipped with a high-precision ball screw and linear guideway. The series of configurations used in the lathe will effectively make the precision of the processed pipe thread meet the requirements of API standard.

This lathe adopts FANUC control system; the spindle is driven by DC 132KW motor.

The automatic charging and discharging mechanism can be equipped, which can realize automatic alignment, charging, feeding, supporting while turning pipes and discharging. All actions of automatic charging and discharging mechanism are controlled by lathe CNC system PLC.

Application:

The specific values of machine productivity are shown in the sheet, and the guaranteed values in the table are the average hourly values for 8 hours of continuous production.| No. | Item | Pipe specification | Productivity/hour | |

|

Outer dia. (mm) |

Length (m) | Guarantee value | ||

| 1 | Oil tube | 60.3mm | 9.75m | 65pcs |

| 2 | Oil tube | 73.02mm | 9.75m | 60pcs |

| 3 | Oil tube | 88.9mm | 9.75m | 56pcs |

| 4 | Oil tube | 114.3mm | 9.75m | 52pcs |

| 5 | Casing pipe | 127mm | 10m | 48pcs |

| 6 | Casing pipe | 139.7mm | 10m | 44pcs |

| 7 | Casing pipe | 177.8mm | 10m | 40pcs |

Parameter:

Parameter:

| ITEM | UNIT | QKH178 | QKH340 | |

| Bed slant angle | ° | 45 | 45 | |

| Capacities | Pipe threading range | mm | φ60-178 | φ140-340 |

| Pipe type | - | ERW; High frequency welded steel pipe; Seamless steel pipe | ERW; High frequency welded steel pipe; Seamless steel pipe | |

| Quality standard of threads | - | API-5B | API-5B | |

| Range of workpiece length | m | 6-12.5 | 6-12.5 | |

| Form of guideway | mm | Linear guideway | Linear guideway | |

| Spindle | Spindle speed range | r/min | 50-900 | 50-500 |

| The distance between spindle center to floor | mm | 1200 | 1200 | |

| Chuck | Front chuck type | - | Hydraulic, pre-centering | Hydraulic, pre-centering |

| Rear chuck type | - | Hydraulic | Hydraulic | |

| Turret | Upper turret type | - | 6-position | 6 positions |

| Lower turret type | - | Fixed | Fixed | |

| Repeat positioning precision of lower turret | mm | ±0.005 | ±0.005 | |

| Others | CNC system | mm | FANUC | FANUC |

| Main motor power | kW | 132 | 132 | |

| Workpiece surface roughness | - | Ra1.6 | Ra1.6 | |

| Width*Height | mm | 2120*2100 | 2410*2100 | |

| Length | mm | 4448 | 4613 | |

| Lathe weight | kg | 16500 | 20000 | |

| Feeding equipment weight | kg | 7000 | 12000 |