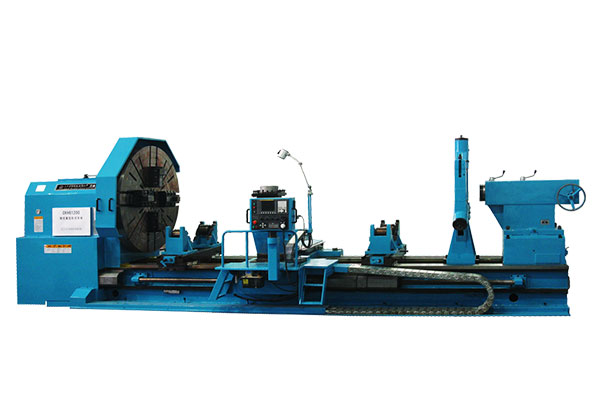

Small conventional lathe:

Features

● Our lathe bed is made of high strength cast iron, and treated by long time aging treatment, so the precision is good and durable.

● Spindle bore diameter φ52/φ80/φ104 mm.

● There are oblique chip outlets in our lathe bed, easy for chip removing.

● Our lathe guide is quenched by induction quenching device, hardened layer thickness is 2-3mm, hardness is 52 HRC.

● DRO, quick change toolpost, grinding attachment, milling power head, rotary tailstock, motorized tailstock are for option.

Parameter:

| Item | Unit | CD6132 | CD6136 | CD6140 | CQ6140 | CQ6240 | CQ6150 | CQ6250 | CQ6161 | CQ6261 | CQ6166 | CQ6266 | |

| Capacity | Swing over bed | mm | φ320 | φ360 | φ400 | 400 | 500 | 610 | 660 | ||||

| Swing over carriage | mm | φ180 | φ200 | φ240 | φ210 | φ300 | φ370 | φ400 | |||||

| Swing over gap | mm | - | - | - | - | 630 | - | 720 | - | 830 | - | 880 | |

| Max. length of workpiece | mm | 750/1000 | 750/1000 | 750/1000 | 1000/2000/3000 | 1000/2000/3000 | 1000/2000/3000 | 1000/2000/3000 | |||||

| Max. turning length | mm | 600/850 | 600/850 | 600/850 | 850/1850/2850 | 850/1850/2850 | 850/1850/2850 | 850/1850/2850 | |||||

| Span of guideway | mm | 312 | 312 | 312 | 400 | 400 | 400 | 400 | |||||

| Spindle | Spindle nose type | - | C6 | C6 | C6 | C6/D8 | C6/D8/D8 | C6/D8/D8 | C6/D8/D8 | ||||

| Spindle taper | - | MT6 | MT6 | MT6 |

MT6/ φ90 1:20 |

MT6/ φ90 1:20/ φ113 1:20 |

MT6/ φ90 1:20/ φ113 1:20 |

MT6/ φ90 1:20/ φ113 1:20 |

|||||

| Spindle bore | mm | φ52 | φ52 | φ52 | φ52/80 | φ52/80/105 | φ52/80/105 | φ52/80/105 | |||||

| No. of spindle speeds | - | 12 | 12 | 12 | 24 | 24 | 24 | 24 | |||||

| Range of spindle speeds | r/min | 30-1600 | 30-1600 | 30-1600 | 16-1400 | 16-1400 | 16-1400 | 16-1400 | |||||

| Toolpost | Cross section of tool shank | mm | 20*20 | 20*20 | 20*20 | 25*25 | 25*25 | 25*25 | 25*25 | ||||

| Tool post type | mm | V4 | V4 | V4 | V4 | V4 | V4 | V4 | |||||

| Max.stroke of upper toolpost | mm | 140 | 140 | 140 | 140 | 140 | 140 | 140 | |||||

| Feed | No. of longitudinal feeding | mm/r | 44; 0.039-1.05 | 44; 0.039-1.05 | 44; 0.039-1.05 | 64 | 64 | 64 | 64 | ||||

| No. of transverse feeding | mm/r | 44; 0.019-0.52 | 44; 0.019-0.52 | 44; 0.019-0.52 | 64 | 64 | 64 | 64 | |||||

| No. and rang of metric threads | - | 25; 0.5-20 | 25; 0.5-20 | 25; 0.5-20 | 44; 1-192 | 44; 1-192 | 44; 1-192 | 44; 1-192 | |||||

| No. and rang of inch threads | TPI | 35; 80-1.75 | 35; 80-1.75 | 35; 80-1.75 | 21; 24-2 | 21; 24-2 | 21; 24-2 | 21; 24-2 | |||||

| No. and rang of modulus threads | - | 24; 0.25-10 | 24; 0.25-10 | 24; 0.25-10 | 39; 0.25-48 | 39; 0.25-48 | 39; 0.25-48 | 39; 0.25-48 | |||||

| No. and rang of diameter pitch threads | - | 30; 160-3.5 | 30; 160-3.5 | 30; 160-3.5 | 37; 1-96 | 37; 1-96 | 37; 1-96 | 37; 1-96 | |||||

| Tailstock | Tailstock quill diameter | mm | 60 | 60 | 60 | 75 | 75 | 75 | 75 | ||||

| Tailstock quill taper | - | MT4 | MT4 | MT4 | MT5 | MT5 | MT5 | MT5 | |||||

| Tailstock quill effective stroke | mm | 100 | 100 | 100 | 150 | 150 | 150 | 150 | |||||

| Others | Main motor power | kW | 3 | 3 | 3 | 7.5 | 7.5 | 7.5 | 7.5 | ||||

| Width*Height | mm | 970*1220 | 970*1250 | 970*1280 | 1000*1267 | 1037*1312 | 1081*1367 | 1106*1392 | |||||

| Length | mm | 1940/2180 | 1940/2180 | 1940/2180 | 2650/3650/4800 | 2650/36504800 | 2650/3650/4800 | 2650/3650/4800 | |||||

| Net weight | kg | 1300/1370 | 1350/1400 | 1400/1450 | 2070/2570/3200 | 2140/2640/3400 | 2250/2787/3600 | 2450/2880/3800 | |||||

| Note: swing over bed/swing over gap/distance between centers (750mm-4000mm) can be customized. | |||||||||||||

Application:

Optional accessories:

1. Gap bed;

2. Digital readout (DRO);

3. Grind attachment vacuum dust collector;

4. Milling attachment;

5. Non-standard chuck and steady rest;

6. Tailstock;

7. Others.