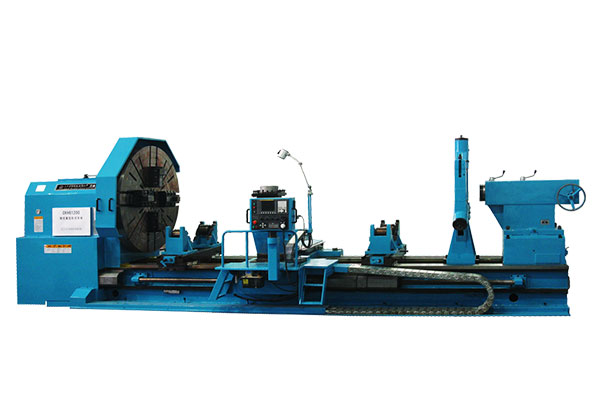

CNC roll turning lathe

CK84 series roll lathe is high precision and high efficiency CNC roll lathe. The machine is combined with advanced technology of CNC roll lathe at home and abroad, using the technology of high speed accuracy spindle, precision feed drive, CNC servo parameter optimization, thermal deformation control, compensation and reliability.

Famous domestic and foreign brand are used to ensure the manufacturing accuracy. The laser detector, dynamic balance test machine, online dynamic balance detector and other advanced testing equipment are used to ensure the machine accuracy.

The machine is not only suitable for processing all kinds of rolling, but also for machining inside and outside circle, cone surface, end face, arc surface, thread and others of shaft, disc and other workpieces. It is widely used in the industries of steel, coal, chemical, automotive oil, military and others. The machine is the first choice equipment of all kinds of rolling factory, steel factory and silver factory.

Main characteristics:

1. The CNC system can be equipped according to the customer’s request. Such as Siemens, Fanuc and others.

2. High speed precision spindle unit, famous large bearing P4 bearing and automatic uninterrupted oil injection lubrication are used to ensure stable precision and long service life.

3. The guide rail adopts four wide rectangular type guideways, which has the characteristics of high speed, high rigidity, good precision retention and so on.

4. The machine is equipped with famous electrical components and high-power thermostatic air conditioning, which ensures the long service life of electrical components and machine stability.

5. The tailstock adopts the built-in rotary center, which greatly improves the tailstock rigidity and machining parts precision.

PARAMETER

| Item | Unit | CK8450 | CKQ8465 | CKQ8485 | CK8465 | CK8485 | CKQ84100 | CK84100 | CK84125 | CK84160 | |

| Capacities | Max. roll turning diameter | mm | φ500 | φ650 | φ850 | φ650 | φ850 | φ1000 | φ1000 | φ1250 | φ1600 |

| Max. length of workpiece | mm |

2500/ 3000 |

2500/ 3000 |

2500/ 3000 |

3500/ 5000 |

3500/ 5000 |

3500/ 5000 |

5000/6000/ 8000 |

5000/6000/ 8000 |

5000/6000/ 8000 |

|

| Max. turning length | mm |

2300/ 3000 |

2300/ 3000 |

2300/ 3000 |

3000/ 4800 |

3000/ 4800 |

3000/ 4800 |

4800/5800/ 7800 |

4800/5800/ 7800 |

4800/5800/ 7800 |

|

| Span of guideways | mm | 850/900 | 850/900 | 850/900 | 1100 | 1100 | 1100 | 1450 | 1450 | 1450 | |

| Max. weight of workpiece | kg | 3600/4000 | 3600/4000 | 3600/4000 | 8000 | 8000 | 8000 | 20000 | 20000 | 20000 | |

| Spindle | Spindle nose type | - | C2-11 | C2-11 | C2-11 | A2-15 | A2-15 | A2-15 | A2-15 | A2-15 | A2-15 |

| Spindle bore | mm | φ100 | φ100 | φ100 | φ130 | φ130 | φ130 | φ96 | φ96 | φ96 | |

| Taper hole of spindle | - | Metric120 | Metric120 | Metric120 | Metric 140 | Metric 140 | Metric 140 | Metric 140 | Metric 140 | Metric 140 | |

| Taper of spindle center | - | MT5 | MT5 | MT5 | MT6 | MT6 | MT6 | MT6 | MT6 | MT6 | |

| Spindle speed range | r/min | 10-500 | 10-500 | 10-500 | 8-350 | 8-350 | 8-350 | 5-200 | 5-200 | 5-200 | |

| Chuck (4-jaw manual) | mm | φ500-630 | φ500-630 | φ500-630 | φ630-800 | φ630-800 | φ630-800 | φ800-1125 | φ800-1125 | φ800-1125 | |

| Turret | Cross section of tool shank | mm | 40*40 | 40*40 | 40*40 | 40*40 | 40*40 | 40*40 | 50*50 | 50*50 | 50*50 |

| Turret type | - | V4 | V4 | V4 | V4 | V4 | V4 | V4 | V4 | V4 | |

| Feed | Max. stroke of X-axis | mm | 330 | 330 | 330 | 450 | 450 | 450 | 450 | 450 | 450 |

| Min. feed of X-axis/Z-axis | mm | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | |

| Rapid traverse speed of X-axis | m/min | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Rapid traverse speed of Z-axis | m/min | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | |

| Tailstock | Tailstock quill diameter | mm | 200 | 200 | 200 | 220 | 220 | 220 | 300 | 300 | 300 |

| Tailstock quill taper | - | MT5 | MT5 | MT5 | MT6 | MT6 | MT6 | MT6 | MT6 | MT6 | |

| Tailstock quill max. stroke | mm | 310 | 310 | 310 | 330 | 330 | 330 | 310 | 310 | 310 | |

| Others | CNC system | - | FANUC | FANUC | FANUC | FANUC | FANUC | FANUC | FANUC | FANUC | FANUC |

| Spindle motor power | kw | AC22 (30) | AC22 (30) | AC22 (30) |

AC30/ AC45 |

AC30/ AC45 |

AC30/ AC45 |

AC75 | AC75 | AC75 | |

| Machining accuracy | - | IT6-IT7 | IT6-IT7 | IT6-IT7 | IT6-IT7 | IT6-IT7 | IT6-IT7 | IT6-IT7 | IT6-IT7 | IT6-IT7 | |

| Surface roughness | μm | Ra 0.8 | Ra 0.8 | Ra 0.8 | Ra 0.8 | Ra 0.8 | Ra 0.8 | Ra 0.8 | Ra 0.8 | Ra 0.8 |