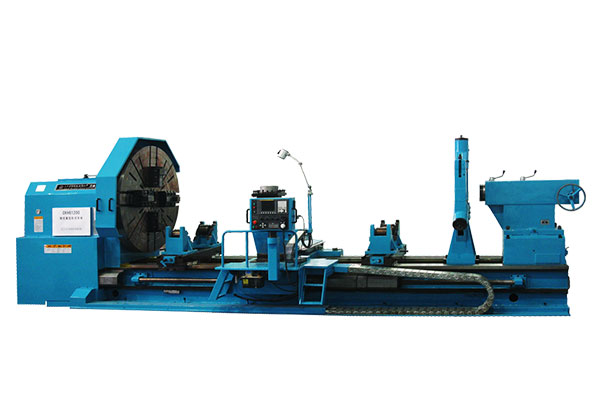

Vertical CNC Lathe CK514A/CK516/CK518

CNC vertical lathes are universal CNC vertical lathes, which are manufactured following the market demand, absorbing the home and abroad peer’s advanced technology, according to the international market latest trend to CNC vertical lathes. It applies to processing various complex spindles, jackets, disk, as well as interior lathe, external cylinder, conical face, arc, end face, grooving, chamfer, drilling hole, expanding hole, threads cutting. Especially for processing medium and small batch products. What’s more, it is with convenient installation, high processing efficiency, and low crap rate, good consistent in finished products, easy programming, and simple operation. Also it can decrease the request to worker’s technology. In a word, it is the ideal machine equipment for cars, motorbikes and other industries for short spindles, disc processing.

Features:

Vertical CNC Lathe

● The max. workpiece for our lathe is 500/600/1500 kg.

● Max. height of workpiece 700/800 mm.

● Both X and Z axes adopt precision linear guides from HIWIN.

● Both X and Z axes adopt precision ball screws from HIWIN with precision FAG ball screw bearings.

● Waterproof hydraulic chuck.

● Precision locknut from Yinsh.

● The precision of All our lathes is measured and compensated by RENISHAW laser interferometer, to make sure both positioning precision and repositioning precision are excellent.

● Hydraulic controlled doule tool toolpost, horizontal hydraulic turret, power tooling turret and milling power head are for option.

High precision vertical CNC Lathe

● X/Z axes repositioning accuracy 0.004 mm, X/Z axes positioning accuracy 0.008 mm, positioning accuracy of C-axis 0.001°

● Ultra-precision spindle, spindle nose runout 0.003/0.004 mm.

● The spindle is equipped with NSK precision bearings.

● Waterproof hydraulic chuck from AUTO STRONG.

● Hydraulic turret from LIO SHING.

● Both X and Z axes adopt precision linear guides from HIWIN.

● Both X and Z axes adopt precision ball screws from HIWIN with precision NSK ball screw bearings.

● Precision locknut from Yinsh.

● Hydraulic controlled doule tool toolpost, horizontal hydraulic turret, power tooling turret and milling power head are for option.

APPLICATION:

TECHNICAL PARAMETERS:

Vertical CNC Lathe

| Item | Unit | VTL500 | VTL700 | VTL900 | VTL1250 | |

| Capacity | Max. swing diameter | mm | φ500 | φ770 | φ970 | φ1300 |

| Max. turning diameter | mm | φ500 | φ700 | φ900 | φ1250 | |

| Max. swing diameter over carriage | mm | φ500 | φ400 | φ600 | φ800 | |

| Max. height of workpiece | mm | 700 | 700 | 700 | 800 | |

| Max. weight of workpiece | kg | 500 | 500 | 600 | 1500 | |

| Rated power of main motor | kW | 11 | 11 | 15 | 15 | |

| Spindle | Spindle speed range | r/min | 50-1200 | 50-1200 | 50-800 | 20-300 |

| Speed ratio of reducer | - | 1:4.84 | 1:4.84 | 1:4.84 | 1:4.84 | |

| Synchronous belt reduction ratio | - | 1:2.5 | 1:2.5 | 1:2.5 | 1:2.5 | |

| Spindle nose type | - | A2-6 | A2-8 | A2-11 | A2-11 | |

| Feed | Max. stroke of X-axis | mm | 300 | 570 | 630 | 810 |

| Max. stroke of Z-axis | mm | 500 | 750 | 750 | 850 | |

| X-axis roller linear rail width | mm | 35 | 45 | 45 | 55 | |

| Z-axis roller linear rail width | mm | 45 | 55 | 55 | 55 | |

| X-axis ball screw diameter * pitch | mm | 32*10 | 40*10 | 40*10 | 50*10 | |

| Z-axis ball screw diameter * pitch | mm | 40*10 | 50*10 | 50*10 | 50*10 | |

| Feeding speed of X-axis/Z-axis | mm/min | 0.05-4000 | 0.05-4000 | 0.05-4000 | 0.05-4000 | |

| Rapid traverse speed of X-axis/Z-axis | m/min | 15 | 15 | 15 | 15 | |

| Feeding motor torque of X-axis/Z-axis | N·m | 15 | 15 | 18 | 23 | |

| Turret | Cross section of tool shank | mm | 32*32 | 32*32 | 32*32 | 32*32 |

| Turret type | - | V4 | V4 | V4 | V4 | |

| Boring bar diameter | mm | φ40 | φ40 | φ40 | φ40 | |

| Precision | Repeat positioning accuracy of X-axis/Z-axis | mm | 0.01 | 0.01 | 0.01 | 0.01 |

| Positioning accuracy of X-axis/Z-axis | mm | 0.02 | 0.02 | 0.02 | 0.02 | |

| Others | CNC system | - | Fanuc 0i-TF | Fanuc 0i-TF | Fanuc 0i-TF | Fanuc 0i-TF |

| Length*Width*Height | mm | 1205*1200*2430 | 1500*1360*2726 | 1550*1760*3067 | 1650*1860*3070 | |

| Net weight | kg | 5000 | 6600 | 8600 | 9600 |

High precision vertical CNC Lathe

| Item | Unit | VLA450 | VLA550 | VLA650 | VLA850 | |

| Capacities | Max. swing diameter | mm | φ600 | φ760 | φ840 | φ950 |

| Max. turning diameter | mm | φ450 | φ550 | φ650 | φ850 | |

| Spindle | Spindle nose | - | A2-8 | A2-8 | A2-11 | A2-11 |

| Spindle bore | mm | φ72 | φ86 | φ86 | φ100 | |

| Spindle speed | r/min | 2500 | 2000 | 1500 | 1200 | |

| Inner diameter of spindle front bearing | mm | φ120 | φ130 | φ160 | φ180 | |

| Chuck diameter | mm/inch | φ304/12 | φ381/15 | φ450/18 | φ610/24 | |

| Spindle end radial runout | mm | 0.003 | 0.003 | 0.003 | 0.004 | |

| Turret | Cross section of tool shank | mm | 25*25 | 25*25 | 25*25 | 32*32 |

| Boring bar diameter | mm | φ40 | φ50 | φ50 | φ50 | |

| Turret type | - | H8 | H8 | H8 | H8 | |

| Tool disc swing | mm | 400 | 450 | 480 | 520 | |

| Stroke | Stroke of X-axis | mm | 270 | 350 | 380 | 880 |

| Stroke of Z-axis | mm | 600 | 700 | 850 | 950 | |

| Servo motor | Spindle servo motor power | kW | 15 | 18.5 | 18.5 | 18.5 |

| Main motor max. torque | N.m | 180 | 240 | 240 | 275 | |

| Spindle max. torque | N·m | 450 | 600 | 720 | 825 | |

| Servo motor power of X-axis | kW | 2.5 | 3 | 3 | 3 | |

| Servo motor torque of X-axis | N·m | Stall torque 20/ Max. torque 45 | Stall torque 27/ Max. torque 68 | Stall torque 27/ Max. torque 68 | Stall torque 30/ Max. torque 83 | |

| Servo motor power of Z-axis | kW | 3 | 3 | 3 | 3 | |

| Servo motor torque of Z-axis | N·m | Stall torque 27/ Max. torque 68 | Stall torque 36/ Max. torque 90 | Stall torque 36/ Max. torque 90 | Stall torque 38/ Max. torque 130 | |

| Rapid traverse | Rapid traverse speed of X-axis | m/min | 16 | 15 | 15 | 12 |

| Rapid traverse speed of Z-axis | m/min | 16 | 15 | 15 | 12 | |

| Accuracy | Repeat positioning accuracy of X-axis/Z-axis | mm | 0.004 | 0.004 | 0.004 | 0.004 |

| Positioning accuracy of X-axis/Z-axis | mm | 0.008 | 0.008 | 0.008 | 0.008 | |

| Hydraulic station | Hydraulic station volume | L | 80 | 80 | 80 | 80 |

| Motor power | kW | 2.2 | 3 | 3.75 | 3.75 | |

| Flow rate | L/min | 30 | 30 | 40 | 40 | |

| Others | CNC system | - | FANUC 0i-TF | FANUC 0i-TF | FANUC 0i-TF | FANUC 0i-TF |

| Length*Width*Height | mm | 1680*3320*2700 | 1850*3500*2700 | 1900*3620*2900 | 2500*3760*3300 | |

| Net weight | kg | 6000 | 8000 | 8600 | 11000 |