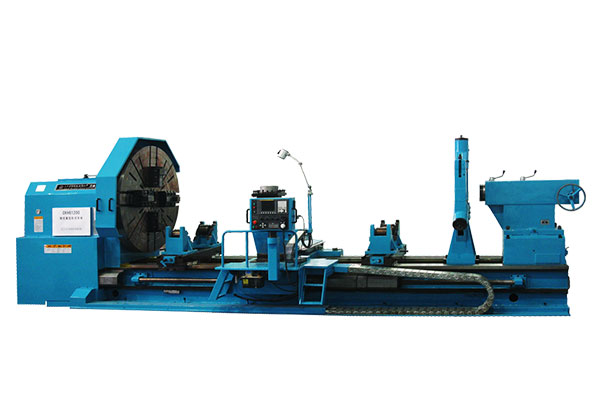

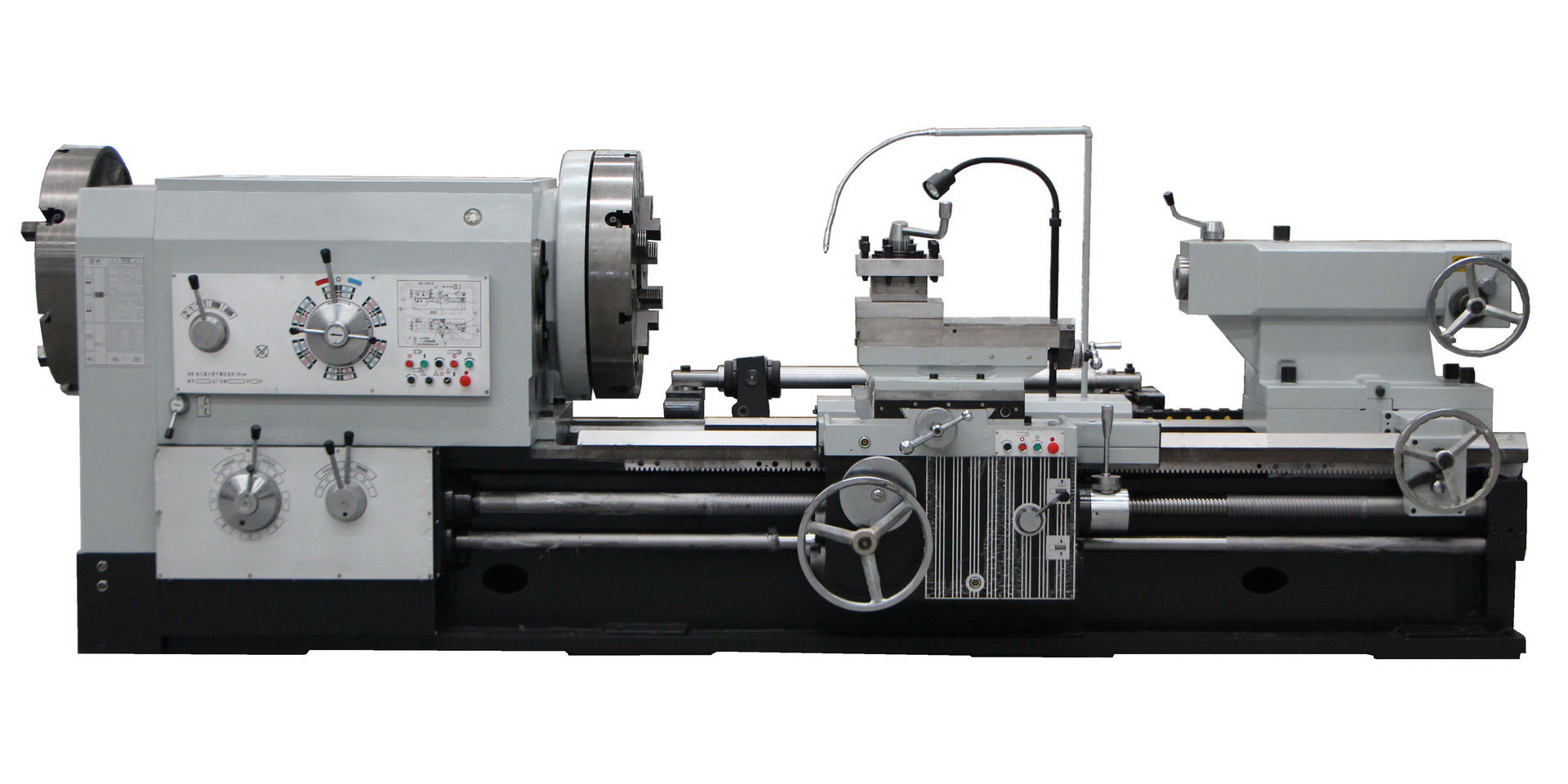

Conventional Pipe Threading Lathe:

Q12 series pipe threading lathe mainly used for turning the internal and external threads including metric and inch thread, as well as having all the common functions of normal engine lathe such as processing the inner bore, end face of shafts and disks, this series is equipped with taper guide bar device which enables this series to process taper thread, this series is widely used in industries including petroleum exploiting, minerals mining, chemical piping and geological prospecting, for processing and repairing drilling pipe, drilling rod, thread coupling and so on.

Characteristics:

Span of guideway:550mm & 600mm

● Spindle bore 130/200/225/280 mm.

● Double hollow chucks.

● The max. workpiece for our lathe is 3000/4000 kg.

● There are oblique chip outlets in our lathe bed, easy for chip removing.

● Our lathe guide is quenched by induction quenching device, hardened layer thickness is 2-3mm, hardness is 52 HRC.

● Taper attachment, quick change toolpost, DRO, grinding attachment, milling power head, rotary tailstock, motorized tailstock are for option.

Span of guideway:755mm

● Spindle bore 280/330/390/440/520 mm.

● Double 4-jaw hollow chucks.

● The max. workpiece for our lathe is 6000 kg.

● There are oblique chip outlets in our lathe bed, easy for chip removing.

● Our lathe guide is quenched by induction quenching device, hardened layer thickness is 2-3mm, hardness is 52 HRC.

● Taper attachment, quick change toolpost, DRO, grinding attachment, milling power head, rotary tailstock, motorized tailstock are for option.

Parameter:

Parameter:

Span of guideway:550mm & 600mm

| ITEMS | UNIT | Q1213 | Q1219 | Q1222 | Q1225 | Q1227 | |

| Capacity | Swing over bed | mm | φ630/800 | φ630/800 | φ630/800 | φ800 | φ800 |

| Swing over carriage | mm | φ340/520 | φ340/520 | φ340/520 | φ480 | φ480 | |

| Distance between centers | mm | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | |

| Pipe threading range | mm | φ30-126 | φ50-193 | φ50-220 | φ50-250 | φ50-270 | |

| Span of guideway | mm | 550 | 550 | 550 | 600 | 600 | |

| Max. weight of workpiece | t | 3 | 3 | 3 | 4 | 4 | |

| Spindle | Spindle bore | mm | φ130 | φ200 | φ225 | φ255 | φ280 |

| Spindle speed regulation | - | Forward: 18 gears; Reverse: 9 gears | Stepless in 4 gears | Stepless in 4 gears | Stepless in 4 gears | Stepless in 4 gears | |

| Spindle speed range | r/min | 30-650 | 20-550 | 20-550 | 20-420 | 20-420 | |

| Chuck | mm | φ400 3-jaw manual | φ520 4-jaw manual | φ520 4-jaw manual | φ630 4-jaw manual | φ630 4-jaw manual | |

| Toolpost | Cross section of tool shank | mm | 30*30 | 32*32 | 32*32 | 32*32 | 32*32 |

| Toolpost type | - | V4 | V4 | V4 | V4 | V4 | |

| Feed | Max. stroke of X-axis | mm | 320/420 | 320/420 | 320/420 | 420 | 420 |

| Max. stroke of Z-axis | mm | 1350/2850 | 1350/2850 | 1350/2850 | 1250/2750 | 1250/2750 | |

| No. and range of X-axis feed | - | 22/0.02-0.45 | 22/0.02-0.45 | 22/0.02-0.45 | 22/0.02-0.45 | 22/0.02-0.45 | |

| No. and range of Z-axis feed | - | 26/0.07-1.33 | 26/0.07-1.33 | 26/0.07-1.33 | 26/0.07-1.33 | 26/0.07-1.33 | |

| Rapid traverse speed of X-axis | mm/min | 2300 | 2300 | 2300 | 2300 | 2300 | |

| Rapid traverse speed of Z-axis | mm/min | 4000 | 4000 | 4000 | 4000 | 4000 | |

| No. and rang of metric threads | - | 52/1-24 | 1-15 | 1-15 | 1-15 | 1-15 | |

| No. and rang of inch threads | - | 40/28-2 | 14-1 | 14-1 | 14-1 | 14-1 | |

| Tailstock | Tailstock quill diameter | mm | φ100 | φ100 | φ100 | φ120 | φ120 |

| Tailstock quill taper | - | MT5 | MT5 | MT5 | MT6 | MT6 | |

| Tailstock quill max. stroke | mm | 250 | 250 | 250 | 250 | 250 | |

| Others | Main motor power | kW | 11 | 11 | 11 | 15 | 15 |

| Rapid traverse motor power | kW | 0.3 | 0.3 | 0.3 | 1.1 | 1.1 | |

| Coolant pump motor power | kW | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | |

| Width*Height | mm | 1500*1500 | 1550*1550 | 1650*1550 | 1700*1600 | 1700*1600 | |

| Length | mm | 3700/5200 | 3700/5200 | 3700/5200 | 4100/5600 | 4100/5600 | |

| Net weight | kg | 4000/5200 | 4300/5500 | 4500/5700 | 8000/9000 | 8000/9000 | |

| Note: swing over bed/distance between centers can be customized. | |||||||

Span of guideway:755mm

| ITEMS | UNIT | Q1227 | Q1232 | Q1238 | Q1243 | Q1250 | |

| Capacity | Swing over bed | mm | φ1000 | φ1000 | φ1000 | φ1000 | φ1200 |

| Swing over carriage | mm | φ610 | φ610 | φ610 | φ610 | φ710 | |

| Distance between centers | mm | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | |

| Pipe threading range | mm | φ130-270 | φ190-320 | φ190-380 | φ270-430 | φ330-510 | |

| Span of guideway | mm | 755 | 755 | 755 | 755 | 755 | |

| Max. weight of workpiece | t | 6 | 6 | 6 | 6 | 6 | |

| Spindle | Spindle bore | mm | φ280 | φ330 | φ390 | φ440 | φ520 |

| Spindle speed regulation | - | Forward: 12 gears | Forward: 9 gears | Forward: 9 gears | Forward: 9 gears | Forward: 9 gears | |

| Spindle speed range | r/min | 16-380 | 7.5-280 | 6-205 | 4.9-180 | 4.9-180 | |

| Chuck | mm | φ800 4-jaw manual | φ780 4-jaw electric | φ850 4-jaw electric | φ1000 4-jaw electric | φ1000 4-jaw electric | |

| Toolpost | Cross section of tool shank | mm | 45*45 | 45*45 | 45*45 | 45*45 | 45*45 |

| Toolpost type | - | V4 | V4 | V4 | V4 | V4 | |

| Feed | Max. stroke of X-axis | mm | 520 | 520 | 520 | 520 | 520 |

| Max. stroke of Z-axis | mm | 1350/2850 | 1350/2850 | 1350/2850 | 1350/2850 | 1350/2850 | |

| No. and range of X-axis feed | - | 40/0.05-1.5 | 32/0.05-0.75 | 32/0.05-0.75 | 32/0.05-0.75 | 32/0.05-0.75 | |

| No. and range of Z-axis feed | - | 40/0.1-3.0 | 32/0.1-1.5 | 32/0.1-1.5 | 32/0.1-1.5 | 32/0.1-1.5 | |

| Rapid traverse speed of X-axis | mm/min | 1870 | 1870 | 1870 | 1870 | 1870 | |

| Rapid traverse speed of Z-axis | mm/min | 3740 | 3740 | 3740 | 3740 | 3740 | |

| No. and rang of metric threads | - | 30/1-30 | 23/1-15 | 23/1-15 | 23/1-15 | 23/1-15 | |

| No. and rang of inch threads | - | 27/28-1 | 22/28-2 | 22/28-2 | 22/28-2 | 22/28-2 | |

| Tailstock | Tailstock quill diameter | mm | φ160 | φ160 | φ160 | φ160 | φ160 |

| Tailstock quill taper | - | MT6 | MT6 | MT6 | MT6 | MT6 | |

| Tailstock quill max. stroke | mm | 300 | 300 | 300 | 300 | 300 | |

| Power system | Main motor power | kW | 22 | 22 | 22 | 22 | 22 |

| Rapid traverse motor power | kW | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Coolant pump motor power | kW | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | |

| Others | Width*Height | mm | 2100*1600 | 2100*1650 | 2100*1700 | 2100*1700 | 2100*1850 |

| Length | mm | 4800/6300 | 4900/6400 | 4900/6400 | 5000/6500 | 5000/6500 | |

| Net weight | kg | 10000/11500 | 11500/13000 | 12800/14300 | 13000/14500 | 15000/16500 | |

| Note: swing over bed/distance between centers can be customized. | |||||||