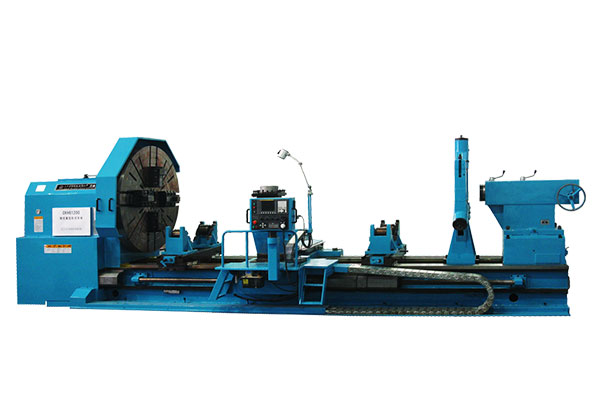

Characteristics:

1. High rigidity casting

Lathe bed, headstock, saddle and tailstock are all made of high rigidity castings. In order to ensure durable precision, those components of lathe will be processed with tempering treatment and long time natural aging treatment.

2. High precision and high rigidity spindle

The spindle is equipped with NSK P4 grade ultra-precision NN type bearings with optimized span (4 bearings in the front and 2 bearings in the back), precision and rigidity are warranted under the condition of high speed rotation and heavy cutting.

3.Precision and heavy duty linear guide and screw

High precision, heavy duty linear guides from Rexroth, HIWIN and PMI with automatic centering function are used. Pre-tightened C3 grade high precision ball screw and long double nuts are applied in our lathe with outstanding precision.

4.Superior quality tailstock

The tailstock quill is controlled by less than 5kg hydraulic pressure, which can effectively prevent deformation of the long shaft workpiece and lathe bed.

5.Multifunctional hydraulic turret and servo turret

Our lathe can be equipped with hydraulic turret and servo turret, drilling power head and milling power head can be installed to realize turning, boring, drilling, tapping and milling processes on one lathe. 4 power heads on the side of turret, another 4 power heads on the end of turret can be installed at the same time, totally 8 power heads with high rotation speed and large torque can be linkaged.

6.Optional C-axis

Technical parameters

Technical parametersSlant bed CNC lathe

| Item | Unit | AE40 | AE45 | AE50 | AE40T | AE46DP | AE50B | |

| Bed slant angle | ° | 45 | 45 | 30 | 45 | 45 | 30 | |

| Capacity | Swing over bed | mm | Φ420 | Φ510 | Φ520 | Φ420 | Φ420 | Φ520 |

| Swing over carriage | mm | Φ400 | Φ450 | Φ500 | Φ400 | Φ360 | Φ500 | |

| Max. length of workpiece | mm | 610 | 820 | 720 | 610 | - | 720 | |

| Max. turning length | mm | 380 | 600 | 500 | 380 |

280 (Turret) 200 (Gang toolpost) |

500 | |

| Max. swing over gang toolpost | mm | - | - | - | - | Φ160 | - | |

| Spindle | Spindle nose type | - | A2-6 | A2-6 | A2-8 | A2-6 | A2-5 | A2-6 |

| Spindle bore | - | Φ56 | Φ62 | Φ82 | Φ56 | Φ48 | Φ62 | |

|

Allowable bar diameter through spindle bore |

mm | Φ50 | Φ55 | Φ75 | Φ50 | Φ42 | Φ55 | |

| Max. spindle speed | r/min | 4500 | 4500 | 3000 | 4500 | 5000 | 4000 | |

| Chuck | inch | 8 | 10 | 12 | 8 | 6 | 10 | |

| Turret | Cross section of tool shank | mm | 25*25 | 25*25 | 25*25 | 25*25 | 20*20 | 25*25 |

| Turret type | - |

Hydraulic turret |

Hydraulic turret |

Hydraulic Turret |

Hydraulic turret |

Hydraulic Turret |

Hydraulic Turret |

|

| No. of switching positions | - | 8 | 8 | 8 | 8 | 8 | 8 | |

| Boring bar diameter | mm | Φ32 | Φ32 | Φ40 | Φ32 | Φ20 (Hydraulic turret) Φ25 (Gang toolpost) | Φ40 | |

|

Stroke & Feed |

X-axis effective stroke | mm | 215 | 230 | 255 | 215 | 780 | 255 |

| Z-axis effective stroke | mm | 400 | 620 | 520 | 400 | 290 | 520 | |

|

Rapid traverse speed of X-axis/Z-axis |

m/min | X:18/Z:24 | X:18/Z:24 | X:24/Z:30 | X:18/Z:24 | X:18/Z:24 | X:24/Z:30 | |

|

Max. feeding speed of X-axis/Z-axis |

m/min | 5 | 5 | 5 | 5 | 5 | 5 | |

| Tailstock | Tailstock quill diameter | mm | Φ80 | Φ80 | Φ80 | Φ80 | - | Φ80 |

| Tailstock quill taper | - | MT5 | MT5 | MT5 | MT5 | - | MT5 | |

| Tailstock quill max. stroke | mm | 100 | 100 | 100 | 100 | - | 100 | |

| Accuracy |

Repeat positioning accuracy of X-axis/Z-axis |

mm | 0.003 | 0.003 | 0.003 | 0.003 | 0.003 | 0.003 |

|

Positioning accuracy of X-axis/Z-axis |

mm | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | |

| Others | Spindle motor power | kW | 11-15 | 11-15 | 11-15 | 11-15 | 7.5-11 | 11-15 |

| Electricity capacity | KVA | 15 | 15 | 15 | 15 | 12 | 15 | |

| CNC system | - |

Siemens 808D |

Siemens 808D |

Siemens 808D |

Siemens 808D |

Siemens 808D |

Siemens 808D |

|

| Length*Width*Height | mm |

2300*1600* 1950 |

2600*1700* 1960 |

2650*1850* 1850 |

2500*1750* 1950 |

2000*1550* 1600 |

2650*1850* 1850 |

|

| Weight | kg | 3000 | 3800 | 4000 | 3000 | 1800 | 4000 | |

Slant bed CNC turning center

| Item | Unit | AE45YD | AE46YD | AE52YD | |

| Capacity | Bed slant angle | ° | 30 | 30 | 30 |

| Swing over bed | mm | φ450 | φ500 | φ500 | |

| Swing over carriage | mm | φ130 | φ200 (Disc type) | φ200 (Disc type) | |

| Max. swing over gang toolpost | mm | φ130 | φ140 | φ140 | |

| Spindle | Spindle nose type | - | A2-5 | A2-5 | A2-6 |

| Spindle bore | mm | φ56 | φ56 | φ66 | |

| Allowable bar diameter through spindle bore | mm | φ40 | φ40 | φ50 | |

| Max. spindle speed | r/min | 4500 | 4500 | 4500 | |

| Collet specification | - | CL42-A5 | CL42-A5 | CL52-A6 | |

| Turret | Cross section of tool shank | mm | 20*20 | 20*20 | 20*20 |

| Turret type | - | Hydraulic turret | Hydraulic Turret | Hydraulic Turret | |

| No. of switching positions | - | 8 | 8 | 8 | |

| Boring bar diameter | mm | φ25 | φ25 | φ25 | |

| Power Head | Power head tool collet Specification | - | ER20 (Axial*4+Radial*4) | ER20 (Axial*4+Radial*4) | ER20 (Axial*4+Radial*4) |

| Max. power head speed | r/min | 3000 | 3000 | 3000 | |

| Max. drilling diameter (Copper and aluminum) | mm | φ12 | φ12 | φ12 | |

| Max. tapping diameter (Copper and aluminum) | mm | M12 | M12 | M12 | |

| Tool diameter | mm | φ2-φ13 | φ2-φ13 | φ2-φ13 | |

| Stroke & Feed | X-axis effective stroke | mm | 500 | 450 | 450 |

| Y-axis effective stroke | mm | 240 | 220 | 220 | |

| Z-axis effective stroke | mm | 450 | 350 | 410 | |

| Rapid traverse speed of X-axis/Z-axis | m/min | X:24/Z:24 | X:30/Z:30 | X:30/Z:30 | |

| Rapid traverse speed of Y-axis | m/min | 15 | 15 | 15 | |

| Accuracy | Repeat positioning accuracy of X-axis/Z-axis | mm | 0.003 | 0.003 | 0.003 |

| Positioning accuracy of X-axis/Z-axis | mm | 0.006 | 0.005 | 0.005 | |

| Others | Spindle motor power | kW | 7.5 | 7.5 | 5.5 |

| Electricity capacity | KVA | 13 | 13 | 16 | |

| CNC system | - | GSK988T | Syntec 21TB | Syntec 21TB | |

| Length*Width*Height | mm | 2500*1800*1800 | 2400*1800*2150 | 2400*1800*2150 | |

| Net weight | kg | 3000 | 3000 | 3000 |

Slant bed CNC turning center

| Item | Unit | AE45Y | AE55Y | |

| Bed slant angle | ° | 45 | 45 | |

| Capacity | Swing over bed | mm | Φ510 | Φ520 |

| Swing over carriage | mm | Φ420 | Φ500 | |

| Max. length of workpiece | mm | 720 | 720 | |

| Max. turning length | mm | 500 | 500 | |

| Max. drilling and milling diameter | mm | 0ºΦ420/90ºΦ420 | - | |

| Spindle | Spindle nose type | - | A2-5 | A2-6 |

| Spindle bore | mm | Φ52 | Φ62 | |

| Allowable bar diameter through spindle bore | mm | Φ45 | Φ55 | |

| Max. spindle speed | r/min | 4500 | 4000 | |

| Chuck | inch | 8 | 10 | |

| Turret | Cross section of tool shank | mm | 20*20 | 25*25 |

| Turret type | - | Power tooling turret | Power tooling turret | |

| No. of switching positions | - | 12 | 12 | |

| Boring bar diameter | mm | Φ25 | Φ32 | |

| Turret motor power | kW | 2.7 | 2.7 | |

| Max. speed of turret motor | r/min | 3000 | 3000 | |

| Live tool holder | - | BMT40 ER16 | - | |

| Power head tool collet Specification | - | - | ER25 | |

| Stroke & Feed | X-axis effective stroke | mm | 230 | 250 |

| Y-axis effective stroke | mm | ±30 | ±50 | |

| Z-axis effective stroke | mm | 500 | 500 | |

| Rapid traverse speed of X-axis/Z-axis | m/min | X:30/Z:30 | X:30/Z:30 | |

| Rapid traverse speed of Y-axis | m/min | 15 | 30 | |

| Max. feeding speed of X-axis/Z-axis | m/min | 5 | 5 | |

| Tailstock | Tailstock quill diameter | mm | Φ80 | Φ80 |

| Tailstock quill taper | - | MT5 | MT5 | |

| Tailstock quill max. stroke | mm | 100 | 100 | |

| Accuracy | Repeat positioning accuracy of X-axis/Z-axis | mm | 0.003 | 0.003 |

| Positioning accuracy of X-axis/Z-axis | mm | 0.005 | 0.005 | |

| Positioning accuracy of C-axis | ° | 0,001 | 0,001 | |

| Others | Spindle motor power | kW | 11-15 | 11-15 |

| Electricity capacity | KVA | 15 | 30 | |

| CNC system | - | Fanuc 0i-TF | Fanuc 0i-TF | |

| Length*Width*Height | mm | 2600*1700*1960 | 2650*1850*1850 | |

| Weight | kg | 3800 | 4500 | |

Slant bed CNC turning center

|

Item |

|

Unit |

AE45CX |

AE55X |

|

Bed slant angle |

° |

45 |

30 |

|

|

Capacity |

Swing over bed |

mm |

Φ510 |

Φ520 |

|

Swing over carriage |

mm |

Φ450 |

Φ500 |

|

|

Max. length of workpiece |

mm |

820 |

720 |

|

|

Max. turning length |

mm |

600 |

500 |

|

|

Spindle |

Spindle nose type |

- |

A2-6 |

A2-6 |

|

Spindle bore |

- |

Φ62 |

Φ62 |

|

|

Allowable bar diameter through spindle bore |

mm |

Φ55 |

Φ55 |

|

|

Max. spindle speed |

r/min |

4500 |

4000 |

|

|

Chuck |

inch |

10 |

10 |

|

|

Turret |

Cross section of tool shank |

mm |

20*20 |

25*25 |

|

Turret type |

- |

Power tooling turret |

Power tooling turret |

|

|

No. of switching positions |

- |

12 |

12 |

|

|

Boring bar diameter |

mm |

Φ20 |

Φ32 |

|

|

Turret motor power |

kw |

2.2 |

2.7 |

|

|

Max. speed of turret motor |

r/min |

4000 |

3000 |

|

|

Rated cutting torque |

N·m |

14 |

- |

|

|

Live tool holder |

- |

VDI30 DIN69880 |

- |

|

|

Power head tool collet Specification |

- |

- |

ER25 |

|

|

Stroke & Feed |

X-axis effective stroke |

mm |

230 |

250 |

|

Z-axis effective stroke |

mm |

620 |

510 |

|

|

Rapid traverse speed of X-axis/Z-axis |

m/min |

X:18/Z:24 |

X:30/Z:30 |

|

|

Max. feeding speed of X-axis/Z-axis |

m/min |

5 |

5 |

|

|

Tailstock |

Tailstock quill diameter |

mm |

Φ80 |

Φ80 |

|

Tailstock quill taper |

- |

MT5 |

MT5 |

|

|

Tailstock quill max. stroke |

mm |

100 |

100 |

|

|

Accuracy |

Repeat positioning accuracy of X-axis/Z-axis |

mm |

0.003 |

0.003 |

|

Positioning accuracy of X-axis/Z-axis |

mm |

0.005 |

0.005 |

|

|

Positioning accuracy of C-axis |

° |

0,001 |

0,001 |

|

|

Others |

Spindle motor power |

kW |

11 |

11-15 |

|

Electricity capacity |

KVA |

20 |

30 |

|

|

CNC system |

- |

Fanuc 0i-TF |

Fanuc 0i-TF |

|

|

Length*Width*Height |

mm |

2800*1600*1950 |

2650*1850*1850 |

|

|

Weight |

kg |

3800 |

4000 |

|