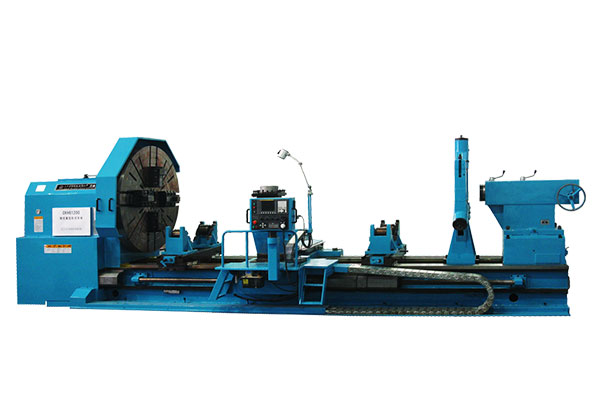

Slant Bed Gang Tool CNC Lathe

This series are slant bed with Gang type tool holder, which not only suitable for processing various precise parts like short shaft and small pan, but also for machining the inner and outer cylindrical surface, conical surface, circular arc surface, end face, grooving, chamfer, threads, drilling, boring and tapping etc. Optional power tool can also do axial or radial drilling and milling on the end face. The slant bed Gang type tool holder show the advantages of strong process adaptability, high stiffness of tool holder, high efficiency (change the knife quickly, forward and reverse turning). Therefore, they are widely used for batch processing of parts such as auto and motorcycle accessories, aerospace, householdappliances, bearing, instruments and meters, valve of hardware etc.

Characteristics:

● Spindle is made of chrome molybdenum alloy steel, with good rigidity, suitable for heavy cutting. ● P4 class precision NSK/NTN spindle bearings. ● HIWIN/PMI P4 class precision ball screw. ● Power tool is for option. ● The precision of All our lathes will be measured and compensated by RENISHAW laser interferometer, to make sure both positioning precision and repositioning precision are excellent. ● GSK980T CNC system.

Parameter:

| Item | Unit | AP32 | AP36 | AP36B | AP46DP | |

| Capacity | Bed slant angle | ° | 30 | 30 | 30 | 45 |

| Swing over bed | mm | Φ320 | Φ360 | Φ360 | Φ420 | |

| Swing over carriage | mm | Φ110 | Φ110 | Φ110 | Φ360 | |

| Max. turning length | mm | 260 | 230 | 330 |

200 (Turret)/ 280 (Gang tool post) |

|

| Max. carriage length | mm | 700 | 700 | 600 | 500 | |

| Spindle | Spindle nose type | - | A2-5 | A2-5 | A2-5 | A2-5 |

| Spindle bore | - | Φ51 | Φ48 | Φ56 | Φ52 | |

| Allowable bar diameter through spindle bore | mm | Φ40 | Φ40 | Φ42 | Φ42 | |

| Max. spindle speed | r/min | 4500 | 4500 | 5000 | 5000 | |

| Spindle motor power | kW | 3.7 | 5.5 | 5.5 | 7.5 | |

| Collet/Chuck specification | - | CL42-A5 Collet | CL42-A5 Collet | CL42-A5 Collet | 6 inch Chuck | |

| Stroke & Feed | Max. X-axis stroke | mm | 300 | 380 | 410 | 750 |

| Max. Z-axis stroke | mm | 280 | 250 | 330 | 290 | |

| Rapid traverse speed of X-axis/Z-axis | m/min | X:20/Z:20 | X:20/Z:20 | X:24/Z:24 | X:18/Z:24 | |

| Max. feeding speed of X-axis/Z-axis | m/min | 5 | 5 | 5 | 5 | |

| Accuracy | Repeat positioning accuracy of X-axis/Z-axis | mm | 0.003 | 0.003 | 0.003 | 0.003 |

| Positioning accuracy of X-axis/Z-axis | mm | 0.006 | 0.006 | 0.006 | 0.005 | |

| Turret | Turret type | - | Gang tool post | Gang tool post | Gang tool post |

Hydraulic turret + Gang tool post |

| No. of switching positions | - | - | - | - | 8 | |

| Cross section of tool shank | mm | 20*20 | 20*20 | 20*20 | 20*20 | |

| Boring bar diameter | mm | Φ25 | Φ25 | Φ25 |

Φ20 (Hydraulic turret)/ Φ25 (Gang tool post) |

|

| Others | CNC system | - | GSK988T | GSK988T | GSK988T | GSK988T |

| Length*Width*Height | mm | 1780*1380*1550 | 2120*1520*1650 | 2600*1700*1600 | 2000*1550*1600 | |

| Weight | kg | 1250 | 1570 | 3000 | 2600 |