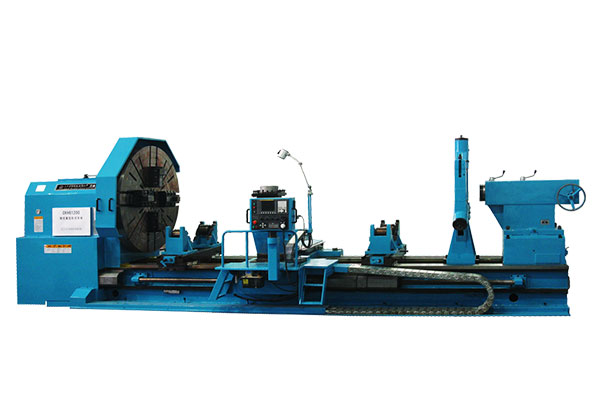

CNC heavy duty lathe

Heavy duty lathe produced by our company has swing over bed diameter from 1250 mm to 3500 mm, distance between centers from 3000 mm to 24000 mm, workpiece weight 10 ton, 12 ton, 16 ton, 20 ton, 32 ton, 40 ton, 63 ton, 80 ton and 100 ton, with CNC control and without CNC control.

Features:

Span of guideway:1100mm

● The max. workpiece for our lathe is 16/20 ton.

● Our lathe is equipped with 1100 mm rectangular guideways.

● Our chuck is K78 series φ1250 /φ1400 /φ1600 /φ2000 mm heavy duty chuck made by Hohhot, the best and most famous chuck manufacturer in China.

● We have Germany made high precision lathe guide grinding machine to ensure the guide precision.

● Motorized rotary tailstock.

● The precision of All our lathes is measured and compensated by RENISHAW laser interferometer, to make sure both positioning precision and repositioning precision are excellent.

Span of guideway:1600mm

● The max. workpiece for our lathe is 32/40 ton.

● Our lathe is equipped with 1600 mm rectangular 3 guideways.

● There are chip outlets at the bottom of our lathe bed, chip drops into chip container in the foundation, easy for chip removing.

● X axis feed adopts Wittenstein Alpha planetary reducer from Germany.

● Z axis feed adopts Atlanta precision gear and gear rack from Germany.

● Stepless speed regulation in the whole spindle speed range.

● Powerful 75kW DC motor from Shanghai Nanyang, the best manufacturer of DC motor in China.

● Disc spring is installed on the back of motorized rotary tailstock spindle to prevent damage to the mechanism due to thermal expansion of the workpiece.

Span of guideway:2090mm

● The max. workpiece for our lathe is 63/80 ton.

● Our lathe is equipped with 2090 mm rectangular 3 guideways.

● SP class spindle bearings.

● Power clamping screws from JAKOB ANTRIEBSTECHNIK from Germany are installed on our chuck.

● Stepless speed regulation in the whole spindle speed range.

● Powerful 144kW DC motor from Shanghai Nanyang, the best manufacturer of DC motor in China.

● Disc spring is installed on the back of motorized rotary tailstock with SP class bearing to prevent damage to the mechanism due to thermal expansion of the workpiece.

Application:

Patameter:

Span of guideway:1100mm

| Item | Unit | CKH61125 | CKH61160 | CKH61200 | CKHJ61125 | CKHJ61160 | CKHJ61200 | |

| Capacity | Swing over bed | mm | φ1250 | φ1600 | φ2000 | φ1250 | φ1600 | φ2000 |

| Swing over carriage | mm | φ900 | φ1250 | φ1600 | φ900 | φ1250 | φ1600 | |

| Max. length of workpiece | mm |

5000/8000/ 12000 |

5000/8000/ 12000 |

5000/8000/ 12000 |

5000/8000/ 12000 |

5000/8000/ 12000 |

5000/8000/ 12000 | |

| Max. turning length | mm |

4800/7800/ 11800 |

4800/7800/ 11800 |

4800/7800/ 11800 |

4800/7800/ 11800 |

4800/7800/ 11800 |

4800/7800/ 11800 | |

| Span of guideway | mm | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | |

| Structure of guideway | - |

Rectangular 2 guideways |

Rectangular 2 guideways |

Rectangular 2 guideways |

Rectangular 2 guideways |

Rectangular 2 guideways |

Rectangular 2 guideways | |

| Max. weight of workpiece | t | 16 | 16 | 16 | 16 | 16 | 16 | |

| Spindle | Spindle nose type | - | A2-15 | A2-15 | A2-15 | A2-15 | A2-15 | A2-15 |

| Spindle center taper | ° | 75 | 75 | 75 | 75 | 75 | 75 | |

| Spindle bore | mm | φ100 | φ100 | φ100 | φ100 | φ100 | φ100 | |

| Spindle speed range | r/min |

3-320 (stepless in 4hydraulic gears) | 3-320 (stepless in 4 hydraulic gears) | 3-320 (stepless in 4 hydraulic gears) | Forward:3.15-315(21gears); Reverse3.5-291(12 gears) | Forward:3.15-315(21gears); Reverse3.5-291(12 gears) |

Forward:3.15-315(21 gears); Reverse3.5-291(12 gears) | |

| Chuck | mm | φ1250 4-jaw manual | φ1400 4-jaw manual | φ1600 4-jaw manual | φ1250 4-jaw manual | φ1400 4-jaw manual | φ1600 4-jaw manual | |

| Turret | Cross section of tool shank | mm | 50*50 | 50*50 | 50*50 | 50*50 | 50*50 | 50*50 |

| Turret type | - | V4 | V4 | V4 | V4 | V4 | V4 | |

| Tailstock | Tailstock quill diameter | mm | 260 | 260 | 260 | 260 | 260 | 260 |

| Tailstock quill taper | - | Metric 80 | Metric 80 | Metric 80 | Metric 80 | Metric 80 | Metric 80 | |

| Tailstock quill max. stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | |

|

Power system | Main motor power | kW | 30 | 30 | 30 | 30 | 30 | 30 |

| Main motor model | - | FANUC α30/6000i | FANUC α30/6000i | FANUC α30/6000i | Y200L-4-B3 | Y200L-4-B3 | Y200L-4-B3 | |

| Main motor speed | r/min | 115/2300 | 115/2300 | 115/2300 | 1470 | 1470 | 1470 | |

| Others | CNC system | - |

FANUC 0i-TF (1) |

FANUC 0i-TF (1) |

FANUC 0i- TF (1) |

FANUC 0i- TF (1) |

FANUC 0i- TF (1) |

FANUC 0i- TF (1) |

| Width*Height | mm | 3200*2220 | 3200*2750 | 3200*2950 | 3200*2220 | 3200*2750 | 3200*2950 | |

| Length | mm |

8400/11400/ 15400 |

8400/11400/ 15400 |

8400/11400/ 15400 |

8400/11400/ 15400 |

8400/11400/ 15400 |

8400/11400/ 15400 | |

| Net weight | kg |

26000/32600/ 41400 |

29500/36100/ 44900 |

33500/40100/ 48900 |

26000/32600/ 41400 |

29500/36100/ 44900 |

33500/40100/ 48900 | |

| Note: swing over bed/distance between centers (3000mm-20000mm) can be customized. | ||||||||

Span of guideway:1600mm

| Item | Unit | CK61160 | CK61200 | CK61250 | |

| Capacity | Swing over bed | mm | φ1600 | φ2000 | φ2500 |

| Swing over carriage | mm | φ1250 | φ1600 | φ2000 | |

| Max. length of workpiece | mm | 5000/8000/12000 | 5000/8000/12000 | 5000/8000/12000 | |

| Span of guideway | mm | 1600 | 1600 | 1600 | |

| Structure of guideway | - | Rectangular 3 guideways | Rectangular 3 guideways | Rectangular 3 guideways | |

| Max. faceplate torque | kN·m | 80 | 80 | 80 | |

| Max. weight of workpiece | t | 32 | 32 | 32 | |

| Spindle | Taper hole of spindle | - | 75°; φ120 | 75°; φ120 | 75°; φ120 |

| Spindle speed regulation | - | Stepless | Stepless | Stepless | |

| Spindle speed range | r/min | 0.8-160 | 0.8-160 | 0.8-160 | |

| Face plate diameter | mm | 1600/1800 | 1600/1800 | 1600/1800 | |

| Chuck | mm | φ1600mm 4-jaw manual | φ1800mm 4-jaw manual | φ2000mm 4-jaw manual | |

| Turret | Cross section of tool shank | mm | 70*70 | 70*70 | 70*70 |

| Turret size | mm | 440*440 | 440*440 | 440*440 | |

| Turret type | - | V4 | V4 | V4 | |

| Max. cutting force of single turret | kN | 80 | 80 | 80 | |

| Total cutting force | kg | 16000 | 16000 | 16000 | |

| Tailstock | Tailstock quill diameter | mm | φ300 | φ300 | φ300 |

| Tailstock quill taper | - | φ100 taper 1:7 | φ100 taper 1:7 | φ100 taper 1:7 | |

| Tailstock quill max. stroke | mm | 300 | 300 | 300 | |

| Power system | Main motor power | kW | 75 | 75 | 75 |

| Spindle motor type | - | DC motor | DC motor | DC motor | |

| Main motor speed | r/min | 400-1200 | 400-1200 | 400-1200 | |

| Others | CNC system | - | FANUC 0i-TF(1) | FANUC 0i-TF(1) | FANUC 0i-TF(1) |

| Width*Height | mm | 2280*3500 | 2280*3500 | 2280*3500 | |

| Length | mm | 10600/13600/176000 | 10600/13600/176000 | 10600/13600/176000 | |

| Note: swing over bed/distance between centers (4000mm-20000mm) can be customized. | |||||

Span of guideway:2090mm

| Item | Unit | CK61250(63T) | |

| Capacity | Swing over bed | mm | φ2500 |

| Swing over carriage | mm | φ2200 | |

| Max.length of workpiece | mm | 5000/8000/12000 | |

| Span of guideway | mm | 2090 | |

| Structure of guideway | - | Rectangular 3 guideways | |

| Max. faceplate torque | kN·m | 120 | |

| Max.weight of workpiece | t | 63 | |

| Spindle | Taper hole of spindle | - | 75° φ196.869 |

| Spindle speed regulation | - | Stepless | |

| Spindle speed range | r/min | 0.5-125 | |

| Face plate diameter | mm | 2200 | |

| Chuck | mm | φ2500mm 4-jaw manual | |

| Turret | Cross section of tool shank | mm | 80*80 |

| Stroke of X-axis (transverse) | mm | 1000 | |

| Rapid traverse speeds of X-axis | mm/min | 3000 | |

| Stroke of Z-axis (longitudinal) | mm | 5000-18000 | |

| Rapid traverse speeds of Z-axis | mm/min | 6000 | |

| Max. stroke of tool plate | mm | 300 | |

| Max. cutting force of single turret | kN | 120 | |

| Total cutting force | kN | 200 | |

| Tailstock | Tailstock quill diameter | mm | 560 |

| Tailstock quill taper | - | 75° φ160 (taper 1:4) | |

| Tailstock quill max. stroke | mm | 200 | |

| Power system | Main motor power | kW | 144 |

| Main drive motor type | - | DC motor | |

| Main drive motor speed range | r/min | 540-1900 | |

| Others | CNC system | - | FANUC 0i-TF(1) |

| Width*Height | mm | 4000*3800 | |

| Length | mm | 12000/15000/19000 | |

| Note: swing over bed/distance between centers (5000mm-20000mm) can be customized. | |||