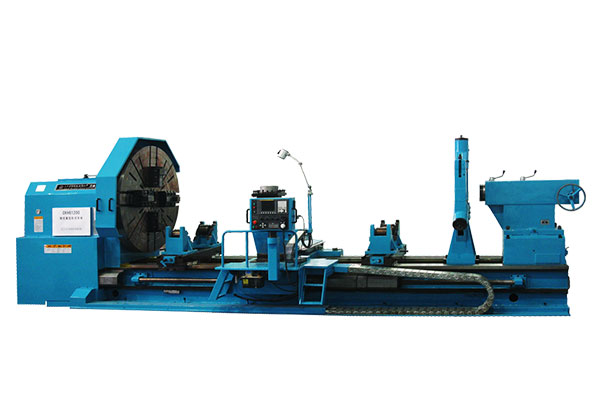

SLANT BED CNC LATHE AD35/45/55

This machine belongs to the full function CNC lathe of semi-closed loop control system.

It applies to processing various complex spindles, jacket, disk. For example, machining interior lathe, conical, arc, end face, grooving, chamfering, and threads. AD-25M is with high speed, high efficiency cutting centre of milling, as well as drilling and milling. Besides, it can complete X, Z, C, three axes association and process various spindles, disc. What’s more, this machine can satisfy the demand for cutting metal, nonferrous metal with high speed.

The lathe design puts emphasison spindle and the stability of heavy cut, which keeps the precision in IT5~IT6. The surface roughness is Ra0.4μm, Ra0.8μm(black metal). As the lathe with high university, especially applies to processing precision parts. Plus, it is with high craft apply ability, high efficiency, high precision, and high quality. In addition, it is widely use d to processing parts of cars, motorbikes, spindle, jackets, aircrafts, home appliances, hydraulic pneumaticsystem, bearings, shaft instruments, and metal valves. In conclusion, it is the ideal metal processing mechanical equipment.

Characteristics:

● Spindle is made of chrome molybdenum alloy steel, with good rigidity, suitable for heavy cutting. ● P4 class precision NSK/NTN spindle bearings. ● Auto Strong hydraulic chuck. ● C3 class ball screw with NSK ball screw bearings. ● GSA hydraulic turret. ● Hydraulic tailstock with programmable quill. ● Fanuc 0i-TF CNC system.

Parameter:

| Item | Unit | AD15B | AD25 | AD35 | AD45 | |

| Bed slant angle | ° | 45 | 45 | 45 | 45 | |

| Capacities | Swing over bed | mm | φ440 | φ520 | φ660 | φ850 |

| Max. length of workpiece | mm | 600/850/1100 | 625/1000/1500/2000/3000 | 890/1640/2000/3000 | 1500/2000/3000 | |

| Max. turning diameter (shaft/disc workpiece) | mm | φ220/φ320 | φ360/φ420 | φ420/φ550 | φ650 /φ800 | |

| Max. turning length | mm | 450/700/950 | 530/905/1405/1905/2905 | 780/1530/1890/2890 | 1420/1920/2920 | |

| Max. weight of workpiece | kg | 500 | 800 | 1000 | 1000 | |

| Spindle | Spindle nose type | - | A2-6 | A2-8 | A2-8 | A2-11 |

| Spindle bore | mm | φ62 | φ87 | φ92 | φ131 | |

| Max. torque of spindle | N·m | 128 | 338 | 652/313 (Dual speed motor) | 1534 | |

| Front bearing inner diameter | mm | φ100 | φ130 | φ160 | 200 | |

| Spindle speed range | r/min | 45-4000 | 35-3500 | 25-2500 | 10-2000 | |

| Bore diameter of hollow hydraulic chuck | mm | φ52 | φ72 | φ81 | φ120 | |

| Chuck | inch | 8 | 10/12 | 12 | 15 | |

| Turret | Cross section of tool shank | mm | 25*25 | 25*25 | 25*25 | 32*32 |

| Turret type | - | H8 (hydraulic) | H12 (hydraulic) | H12 (hydraulic) | H12 (hydraulic) | |

| Max. boring diameter | mm | φ40 | φ40 | φ50 | φ60 | |

| Stroke & Feed | Stroke of X-axis | mm | 190 | 230 | 305 | 450 |

| Stroke of Z-axis | mm | 460/710/960 | 590/965/1465/1965/2965 | 855/1605/1965/2965 | 1450/1950/2950 | |

| Rapid traverse speed of X-axis | m/min | 18 | 12 | 12 | 12 | |

| Rapid traverse speed of Z-axis | m/min | 20 | 15 | 15 | 15 | |

| Tailstock | Tailstock stroke | mm | 460 | 490/865/1365/1865/2865 | 706/1456/1816/2816 | 1900 |

| Tailstock quill diameter | mm | φ80 | φ85 | φ110 | φ140 | |

| Tailstock quill taper | - | MT 5 | MT 5 | MT 5 | MT 6 | |

| Tailstock quill max. stroke | mm | 80 | 80 | 100 | 130 | |

| Others | Main motor power | kW | Fanuc AC11/9 | Fanuc AC18.5/15 | Fanuc AC30/22 | Fanuc AC100 |

| CNC system | - | Fanuc 0i-TF(5) | Fanuc 0i-TF(1) | Fanuc 0i-TF(1) | Fanuc 0i-TF(1) | |

| Width*Heigh | mm | 1485*1700 | 1545*1950 | 1820/2130 | 2350/2600 | |

| Length | mm | 2575/2875/3470 | 3000/3380/4550/4960/6160 | 3620/4725/5825/7000 | 6360/6860/7860 | |

| Net weight | kg | 3600/4200/4800 | 5000/5500/6500/7500/8500 | 8000/10000/11000/15000 | 15000/16000/18000 |