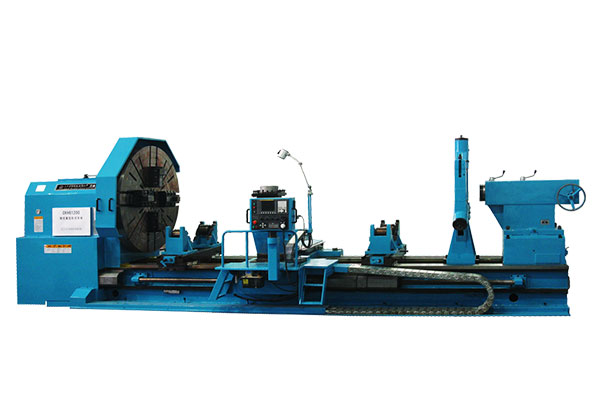

High speed cnc lathe machines:

This series are economical and practical CNC lathes, which are not only suitable for all kinds of complex shape of the shaft, sets, disk parts of the internal and external surfaces, conical surface, but also can be used in automotive, petroleum, military and other mechanical processing. The lathe has advantages such as high efficiency, low scrap rate, good consistency, etc.

CKB series economic practical CNC lathe adopts the whole bed, guide rail width of 600 mm, with a half closed loop control function, is widely applied in industries such as automobile, petroleum, military industry machining of large parts.

Features of cnc lathes:

1. Easy operation

2. Reasonable structure

3. Attractive price

4. Maintenance simple

5. High efficiency

6. Automatic control

Application:

Parameter:

Span of guideway:550mm

| Item | Unit | CK6163 | CK6263 | CK6180 | CK6280 | CK6194 | CK6294 | CKP6163 | CKP6263 | CKP6180 | CKP6280 | CKP6194 | CKP6294 | |

| Capacity | Swing over bed | mm | φ630 | φ800 | φ940 | φ630 | φ800 | φ940 | ||||||

| Swing over carriage | mm | φ340 | φ510 | φ650 | φ340 | φ510 | φ650 | |||||||

| Swing over gap | - | φ800 | - | φ970 | - | φ1110 | - | φ800 | - | φ970 | - | φ1110 | ||

| Max. length of workpiece | mm | 1500/2000/3000 | 1500/2000/3000 | 1500/2000/3000 | 1500/2000/3000 | 1500/2000/3000 | 1500/2000/3000 | |||||||

| Max. turning length | mm | 1350/1850/2850 | 1350/1850/2850 | 1350/1850/2850 | 1350/1850/2850 | 1350/1850/2850 | 1350/1850/2850 | |||||||

| Span of guideway | mm | 550 | 550 | 550 | 550 | 550 | 550 | |||||||

| Max. weight of workpiece | t | 1.5/3 | 1.5/3 | 1.5/3 | 2/4 | 2/4 | 2/4 | |||||||

| Spindle | Spindle nose type | - | C11 | C11 | C11 | C11 | C11 | C11 | ||||||

| Spindle center taper | - | MT5 | MT5 | MT5 | MT5 | MT5 | MT5 | |||||||

| Spindle bore | mm | φ100 | φ100 | φ100 | φ100 | φ100 | φ100 | |||||||

| Spindle speed range | r/min | 12.5-1000 (stepless in 4 hydraulic gears) | 10-800 (stepless in 4 hydraulic gears) | 10-800 (stepless in 4 hydraulic gears) | 27-1000 (stepless in 4 manual gears) | 22-800 (stepless in 4 manual gears) | 22-800 (stepless in 4 manual gears) | |||||||

| Turret | Cross section of tool shank | mm | 32*32 | 32*32 | 32*32 | 32*32 | 32*32 | 32*32 | ||||||

| Turret type | - | V4 | V4 | V4 | V4 | V4 | V4 | |||||||

| Feed | Min. feed of X-axis/Z-axis | mm | 0.001/0.001 | 0.001/0.001 | 0.001/0.001 | 0.001/0.001 | 0.001/0.001 | 0.001/0.001 | ||||||

| Rapid traverse speed of X-axis/Z-axis | mm/min | 3000/6000 | 3000/6000 | 3000/6000 | 3000/6000 | 3000/6000 | 3000/6000 | |||||||

| Max. stroke of X-axis | mm | 390 | 475 | 475 | 390 | 475 | 475 | |||||||

| Tailstock | Tailstock quill diameter | mm | φ100 | φ100 | φ100 | φ100 | φ100 | φ100 | ||||||

| Tailstock quill taper | - | MT5 | MT5 | MT5 | MT5 | MT5 | MT5 | |||||||

| Tailstock quill max. stroke | mm | 250 | 250 | 250 | 250 | 250 | 250 | |||||||

| Power system | Main motor power | kW | 11 | 11 | 11 | 11 | 11 | 11 | ||||||

| Main motor speed | r/min | 1460 | 1460 | 1460 | 1460 | 1460 | 1460 | |||||||

| Others | CNC system | - | Fanuc 0i-TF(5) | Fanuc 0i-TF(5) | Fanuc 0i-TF(5) | Fanuc 0i-TF(5) | Fanuc 0i-TF(5) | Fanuc 0i-TF(5) | ||||||

| Width*Height | mm | 1800*1880 | 1880*1930 | 1880*1930 | 1800*1880 | 1880*1930 | 1880*1930 | |||||||

| Length | mm | 3895/4390/5390 | 3895/4390/5390 | 3895/4390/5390 | 3895/4390/5390 | 3895/4390/5390 | 3895/4390/5390 | |||||||

| Net weight | kg | 4000/4500/5000 | 4400/4900/5400 | 4700/5200/5700 | 4000/4500/5000 | 4400/4900/5400 | 4700/5200/5700 | |||||||

| Note: swing over bed/swing over gap/distance between centers (1000mm-8000mm)/ CNC system (FANUC/SIEMENS/GSK/KND) can be customized. | ||||||||||||||

Span of guideway:600mm

| Item | Unit | CKB6180 | CKB61100 | CKBP6180 | CKBP61100 | |

| Capacity | Swing over bed | mm | φ800 | φ1000 | φ800 | φ1000 |

| Swing over carriage | mm | φ480 | φ680 | φ480 | φ680 | |

| Swing over gap | - | - | - | - | ||

| Max. length of workpiece | mm | 1500/2000/3000 | 1500/2000/3000 | 1500/2000/3000 | 1500/2000/3000 | |

| Max. turning length | mm | 1350/1850/2850 | 1350/1850/2850 | 1350/1850/2850 | 1350/1850/2850 | |

| Span of guideway | mm | 600 | 600 | 600 | 600 | |

| Max. weight of workpiece | t | 2.5/4 | 2.5/4 | 2.5/4 | 2.5/4 | |

| Spindle | Spindle nose type | - | C11/C15 | C11/C15 | C11/C15 | C11/C15 |

| Spindle center taper | - | MT6 | MT6 | MT6 | MT6 | |

| Spindle bore | mm | φ100/φ140 | φ100/φ140 | φ100/φ140 | φ100/φ140 | |

| Spindle speed range | r/min | 8-800 (stepless in 4 hydraulic gears) | 8-800 (stepless in 4 hydraulic gears) | 8-800 (stepless in 4 manual gears) | 8-800 (stepless in 4 manual gears) | |

| Turret | Cross section of tool shank | mm | 32*32 | 32*32 | 32*32 | 32*32 |

| Turret type | - | V4 | V4 | V4 | V4 | |

| Feed | Min. feed of X-axis/Z-axis | mm | 0.001/0.001 | 0.001/0.001 | 0.001/0.001 | 0.001/0.001 |

| Rapid traverse speed of X-axis/Z-axis | mm/min | 4000/5000 | 4000/5000 | 4000/5000 | 4000/5000 | |

| Max. stroke of X-axis | mm | 420 | 420 | 420 | 420 | |

| Tailstock | Tailstock quill diameter | mm | φ100 | φ100 | φ100 | φ100 |

| Tailstock quill taper | - | MT6 | MT6 | MT6 | MT6 | |

| Tailstock quill max. stroke | mm | 250 | 250 | 250 | 250 | |

| Power system | Main motor power | kW | 15 | 15 | 15 | 15 |

| Main motor speed | r/min | 970 | 970 | 970 | 970 | |

| Others | CNC system | - | Fanuc 0i-TF(5) | Fanuc 0i-TF(5) | Fanuc 0i-TF(5) | Fanuc 0i-TF(5) |

| Width*Height | mm | 1985*2105 | 1985*2105 | 1985*2105 | 1985*2105 | |

| Length | mm | 3970/4510/5465 | 3970/4510/5465 | 3970/4510/5465 | 3970/4510/5465 | |

| Net weight | kg | 5300/5600/6000 | 5600/5900/6300 | 5300/5600/6000 | 5600/5900/6300 | |

| Note: swing over bed/swing over gap/distance between centers (1000mm-8000mm)/ CNC system (FANUC/SIEMENS/GSK/KND) can be customized. | ||||||

Standard configuration:

1.The control system uses GSK 980T, can be changed to Fanuc or Siemens..

2.The main motor adopts domestic frequency conversion motor 15kw/22Kw.

3.The X / Z motor adopts servo motor.

4.The tool holder adopts vertical four-position electric knife holder.(V6/V8 optional).

5.X / Z direction uses domestic famous precision ball screw.

7.Manual jaw self-centering chuck.

8.Manual tailstock.

9.Spindle hydraulic automatic four gear speed, stepless speed within the file speed.

10.The main electrical components adopt Schneider brand.