Fire sprinkler production line video:

Flow chart of fire sprinkler production line:

Nowadays, almost all buildings are equipped with fire sprinkler system. There are huge demand of fire sprinklers in the world very year. Fire sprinkler production line is developed under such circumstances by Anyang Xinheng Machine Tool Co., Ltd, and this production line is widely applied in fire sprinkler filed.

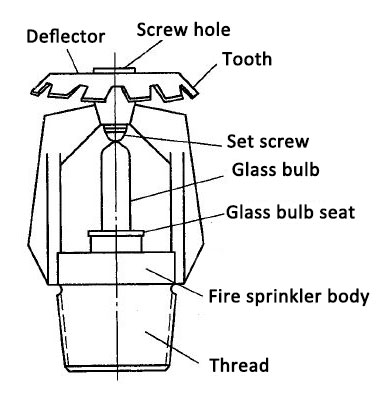

The whole processes, including brass rod cutting, heating, hot forging, trimming, shot blasting, machining, deflector assembling, glass bulb seat machining, O ring assembling, final assembling and pressure testing, are fully automatic with very few labor cost.

I. Product range

All ordinary fire sprinklers, such us pendent, uprights, sidewalls, and concealed sprinklers, can be produced by our production line.

The productivity can be customized according customer’s actual requirement.

II. Key equipment introduction

1. Automatic heating furnace

The unordered brass billets in bulk can be charged in one time to automatic feeder of heating furnace, brass billets will be fed into furnace chamber one by one automatically.

2. Automatic hot forging press with robot/without robot

We not only provide client qualified hot forging press, but also die rack and dies for fire sprinklers. No matter our client has experience in hot forging or not, our client can start hot forging production for fire sprinklers as soon as they receive the press.

3. Trimming press

4. Automatic CNC lathe for fire sprinkler

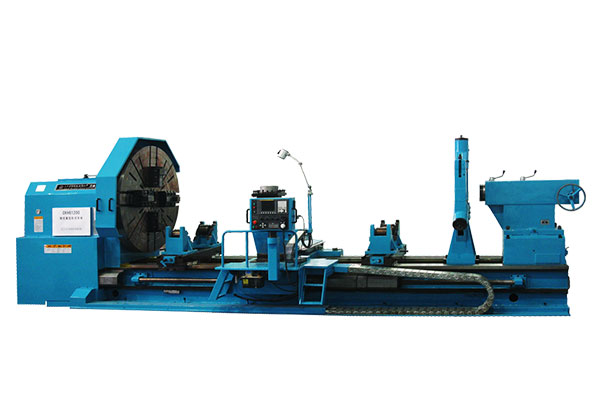

Our automatic CNC lathe is specialized developed for fire sprinkler production. The whole processes, feeding, clamping, turning, chamfering, threading, boring and drilling are fully automatic, so one operator can operate 24 sets of automatic CNC lathes. Those lathes are divided into 2 groups, the first group of lathes are used to process A face of sprinkler frame; the second group of lathes are used to process B face of sprinkler frame. On average, every 23 seconds, one piece of fire sprinkler frame can be done on one set of our CNC lathe. The production efficiency is greatly improved.

5. O ring assembling machine

The main function of Automatic O Ring Assembling Machine for Glass Bulb Seat is to install the sealing ring on the glass bulb seat of sprinkler. The automatic O ring assembling machine has two matching automatic feeding devices. One of the automatic feed devices is used to feed the seat of the glass bubble, and the other is used to feed the seal ring.

6. Glass bulb assembling machine

Automatic installation machine for glass bubble is mainly used for the installation of the sprinkler’s glass bubble.

7. Pressure testing machine

Glass ball tester is used to check whether the quality of the sprinkler’s glass bulb is up to the standard.