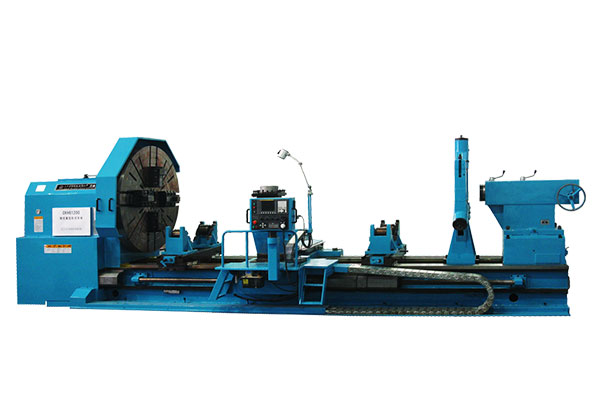

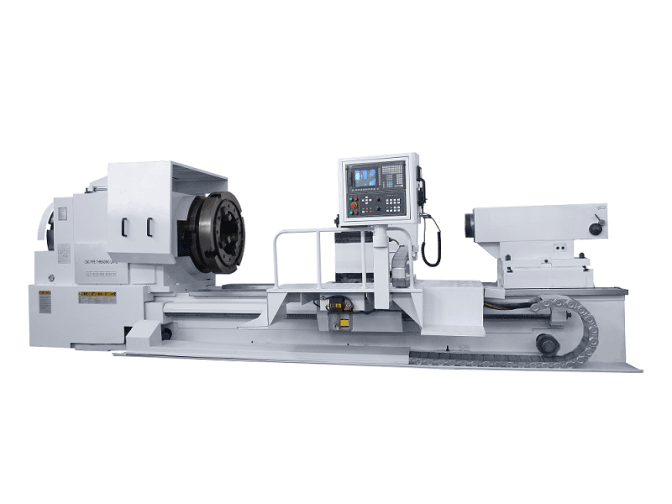

QK series cnc pipe threading lathe (oil country lathe):

The oil country lathe is mainly developed for the pipe thread turning in the oilfield and is suitable for turning of various pipe threads. The lathe belongs to a universal CNC pipe threading lathe of a semi-closed-loop control system and also can be used as a common CNC lathe, and is suitable for machining complicated shapes shaft, sleeve, disk parts. Such as turning, cylindrical surface, conical surface, arc surface, face, grooving, chamfering, thread and so on.

Characteristics:

(1) The lathe body isintegralcasting structure.

(2) Strong rigidity headstock which can adapt to heavy processing.

(3) CNC system uses FANUC 0i Mate-TD (also according to customers’ requirements match other systems)

(4) The spindle bore is 200mm, it is easy and enough for customer to feed pipes through the spindle bore, it can not only machining the surface for the bearing, but also can machining the thread or screw.

(5) We can customize the automatic feeding device according to different workpiece, the production will be competitive.

Application:

All kinds of drill pipe & drill collar, oil pipes and so on.

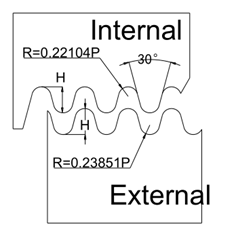

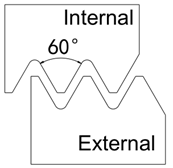

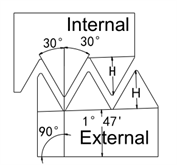

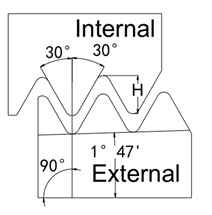

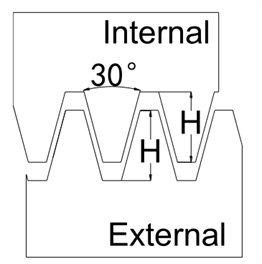

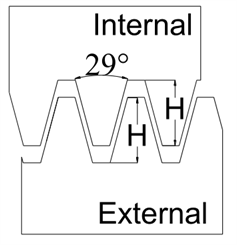

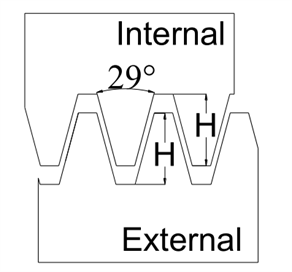

| Threadtype | |||

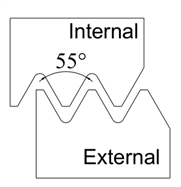

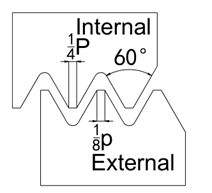

| 60°general pitchthreads |  | 55°general pitchthreads |  |

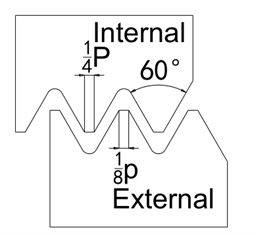

| 60°ISO metricthreads |  | Unified threads(Americanstandard) |  |

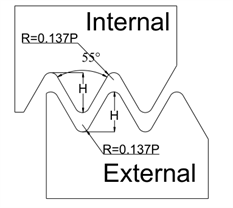

| Whitworth threads |  | American standard taper pipe threads |  |

| NPTF |  | TR |  |

| ACME |  | SACME |  |

| RD |

| ||

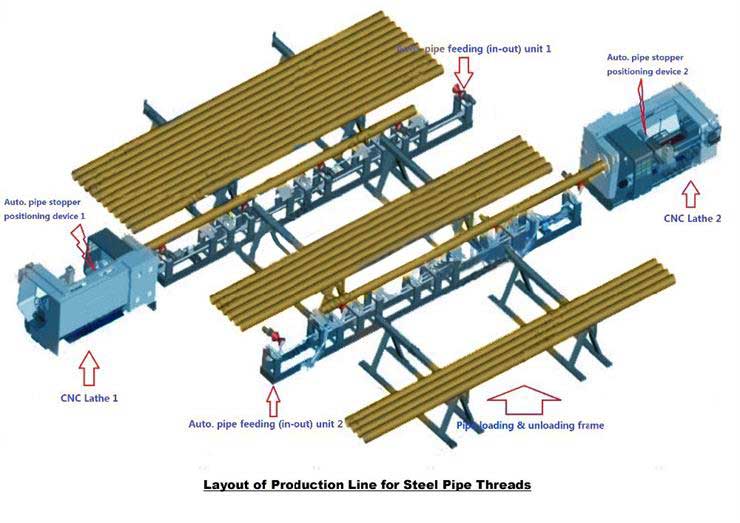

The layout of the cnc pipe threading lathes:

Parameter:

Span of guideway:550mm

| ITEMS | UNIT | QKJ1213 | QK1219 | QK1222 | |

| Capacity | Swing over bed | mm | φ630/800 | φ630/800 | φ630/800 |

| Swing over carriage | mm | φ340/520 | φ340/520 | φ340/520 | |

| Distance between centers | mm | 1000/1500/3000 | 1000/1500/3000 | 1000/1500/3000 | |

| Pipe threading range | mm | φ30-126 | φ50-193 | φ50-220 | |

| Span of guideway | mm | 550 | 550 | 550 | |

| Max. weight of workpiece | t | 3 | 3 | 3 | |

| Spindle | Spindle bore | mm | φ130 | φ200 | φ225 |

| Spindle speed regulation | - | stepless in 3 manual gears | stepless in 4 manual /hydraulic gears | stepless in 4 manual /hydraulic gears | |

| Spindle speed range | r/min | 30-720 | 20-550 | 20-550 | |

| Chuck | mm | φ400 3-jaw manual | φ500 3-jaw manual | φ500 3-jaw manual | |

| Turret | Cross section of tool shank | mm | 32*32 | 32*32 | 32*32 |

| Turret type | - | V4 | V4 | V4 | |

| Feed | Max. stroke of X-axis | mm | 320/420 | 320/420 | 320/420 |

| Max. stroke of Z-axis | mm | 850/1350/2850 | 850/1350/2850 | 850/1350/2850 | |

| Rapid traverse speed of X-axis | mm/min | 4000 | 4000 | 4000 | |

| Rapid traverse speed of Z-axis | mm/min | 6000 | 6000 | 6000 | |

| Tailstock | Tailstock quill diameter | mm | φ100 | φ100 | φ100 |

| Tailstock quill taper | - | MT5 | MT5 | MT5 | |

| Tailstock quill max. stroke | mm | 250 | 250 | 250 | |

| Power system | Main motor power | kW | 11 | 11 | 11 |

| Coolant pump motor power | kW | 0.125 | 0.125 | 0.125 | |

| Others | CNC system | - | Siemens 808D | Siemens 808D | Siemens 808D |

| Width*Height | mm | 1800*1850 | 1880*1850 | 1880*1850 | |

| Length | mm | 3300/3800/5300 | 3300/3800/5300 | 3300/3800/5300 | |

| Net weight | kg | 4500/5000/6000 | 4600/5100/6100 | 4700/5200/6200 | |

| Note: swing over bed/distance between centers can be customized. | |||||

Span of guideway:600mm

| ITEMS | UNIT | QK1225 | QK1227 | |

| Capacity | Swing over bed | mm | φ800 | φ800 |

| Swing over carriage | mm | φ480 | φ480 | |

| Distance between centers | mm | 1000/1500/3000 | 1000/1500/3000 | |

| Pipe threading range | mm | φ120-250 | φ130-270 | |

| Span of guideway | mm | 600 | 600 | |

| Max. weight of workpiece | t | 4 | 4 | |

| Spindle | Spindle bore | mm | φ255 | φ280 |

| Spindle speed regulation | - | stepless in 4 manual /hydraulic gears | stepless in 4 manual /hydraulic gears | |

| Spindle speed range | r/min | 20-420 | 20-420 | |

| Chuck | mm | φ630 4-jaw manual | φ630 4-jaw manual | |

| Turret | Cross section of tool shank | mm | 32*32 | 32*32 |

| Turret type | - | V4 | V4 | |

| Feed | Max. stroke of X-axis | mm | 420 | 420 |

| Max. stroke of Z-axis | mm | 850/1350/2850 | 850/1350/2850 | |

| Rapid traverse speed of X-axis | mm/min | 4000 | 4000 | |

| Rapid traverse speed of Z-axis | mm/min | 6000 | 6000 | |

| Tailstock | Tailstock quill diameter | mm | φ120 | φ120 |

| Tailstock quill taper | - | MT6 | MT6 | |

| Tailstock quill max. stroke | mm | 250 | 250 | |

| Power system | Main motor power | kW | 15 | 15 |

| Coolant pump motor power | kW | 0.125 | 0.125 | |

| Others | CNC system | - | Siemens 808D | Siemens 808D |

| Width*Height | mm | 1930*1900 | 1930*1900 | |

| Length | mm | 3600/4100/5600 | 3600/4100/5600 | |

| Net weight | kg | 6000/6500/7500 | 6200/6700/7700 | |

| Note: swing over bed/distance between centers can be customized. | ||||

Span of guideway:755mm

| ITEMS | UNIT | QK1232 | QK1238 | QK1243 | QK1250 | QK1263 | |

| Capacity | Swing over bed | mm | φ1000 | φ1000 | φ1000 | φ1200 | φ1400 |

| Swing over carriage | mm | φ610 | φ610 | φ610 | φ710 | φ800 | |

| Distance between centers | mm | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | |

| Pipe threading range | mm | φ190-320 | φ190-380 | φ270-430 | φ330-510 | φ330-630 | |

| Span of guideway | mm | 755 | 755 | 755 | 755 | 1100 | |

| Max. weight of workpiece | t | 6 | 6 | 6 | 6 | 10 | |

| Spindle | Spindle bore | mm | φ330 | φ390 | φ440 | φ520 | φ640 |

| Spindle speed regulation | - |

stepless in 3 manual/ hydraulic gears |

stepless in 3 manual/ hydraulic gears |

stepless in 3 manual/ hydraulic gears |

stepless in 3 manual/ hydraulic gears |

stepless in 3 manual/ hydraulic gears | |

| Spindle speed range | r/min | 10-280 | 8-205 | 8-205 | 8-190 | 2-120 | |

| Chuck | mm | φ780 4-jaw electric | φ850 4-jaw electric | φ1000 4-jaw electric | φ1000 4-jaw electric | φ1250 4-jaw manual | |

| Turret | Cross section of tool shank | mm | 40*40 | 40*40 | 40*40 | 50*50 | 50*50 |

| Turret type | - | V4 | V4 | V4 | V4 | V4 | |

| Feed | Max. stroke of X-axis | mm | 520 | 520 | 520 | 520 | 750 |

| Max. stroke of Z-axis | mm | 1250/2750 | 1250/2750 | 1250/2750 | 1250/2750 | 1250/2750 | |

| Rapid traverse speed of X-axis | mm/min | 4000 | 4000 | 4000 | 4000 | 4000 | |

| Rapid traverse speed of Z-axis | mm/min | 4000 | 4000 | 4000 | 4000 | 4000 | |

| Tailstock | Tailstock quill diameter | mm | φ160 | φ160 | φ160 | φ160 | φ260 (rotary quill) |

| Tailstock quill taper | - | MT6 | MT6 | MT6 | MT6 | Metric 80 | |

| Tailstock quill max. stroke | mm | 300 | 300 | 300 | 300 | 300 | |

|

Power system | Main motor power | kW | 22 | 22 | 22 | 22 | 37 |

| Coolant pump motor power | kW | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | |

| Others | CNC system | - | Siemens 808D | Siemens 808D | Siemens 808D | Siemens 808D | Siemens 808D |

| Width*Height | mm | 2080*2080 | 2220*2120 | 2220*2120 | 2300*2200 | 2500*2500 | |

| Length | mm | 5000/6500 | 5000/6500 | 5000/6500 | 5000/6500 | 5600/7100 | |

| Net weight | kg | 11500/12500 | 12000/13000 | 13000/14000 | 15000/16000 | 18000/19300 | |

| Note: swing over bed/distance between centers can be customized. | |||||||

Standard configuration of the cnc pipe threading lathes:

1.CNC System:FANUC Series0i-mate-TD/0i-TD

2. X, Z motor with Fanuc feed servo motor 12Nm, 22Nm

3. Vertical 4-station electric turret 240X240/ 300×300/ 380×380

4. Guide rail width: 550mm/ 600mm/ 755mm

5. Spindle manual 3 files, hydraulic automatic 6 files, a total of 16 speed

6. Spindle bore 130mm/ 200mm/ 240mm

7.Double standard three-jaw self-centering chuck 380mm

8.The main hydraulic components use the Shanghai Electrical andMechanical Services.

9. Semi-protection.